TAILOR-MADE PARTS FOR YOUR PROJECT

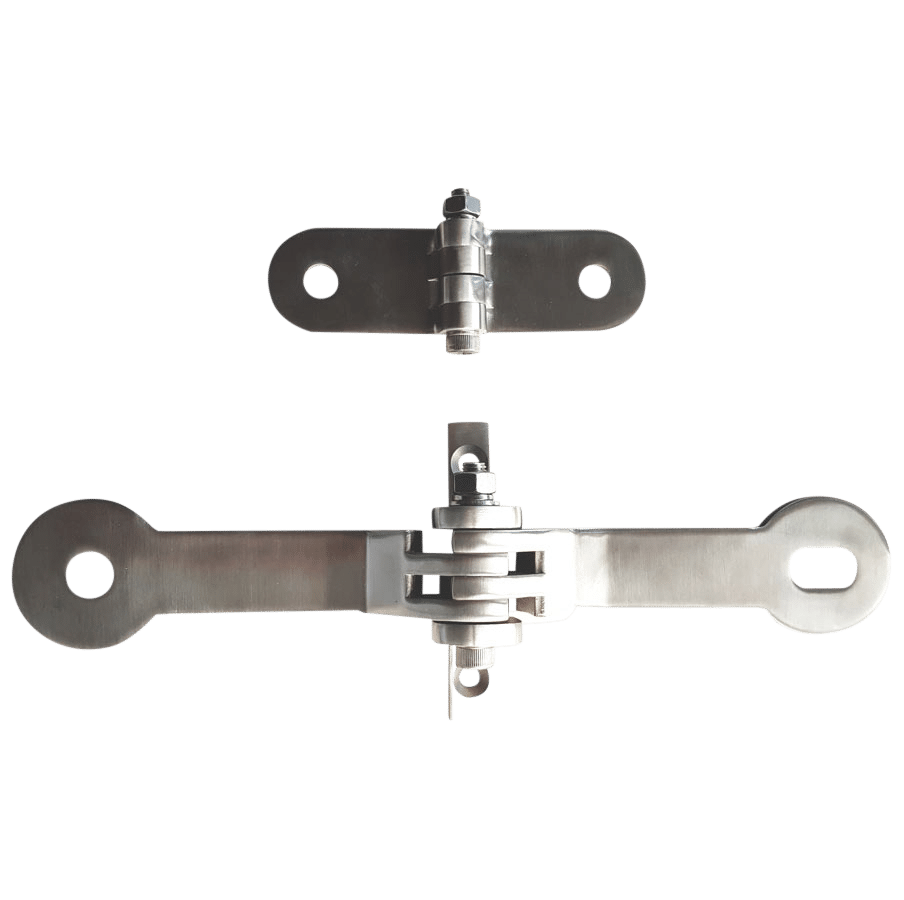

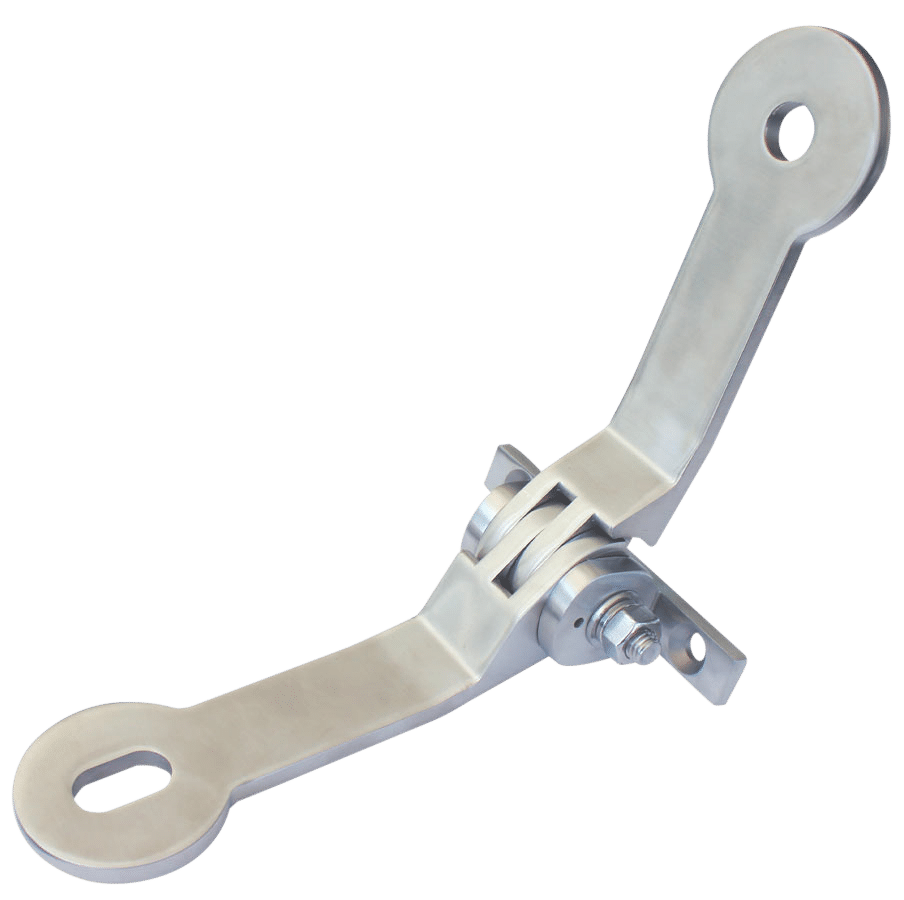

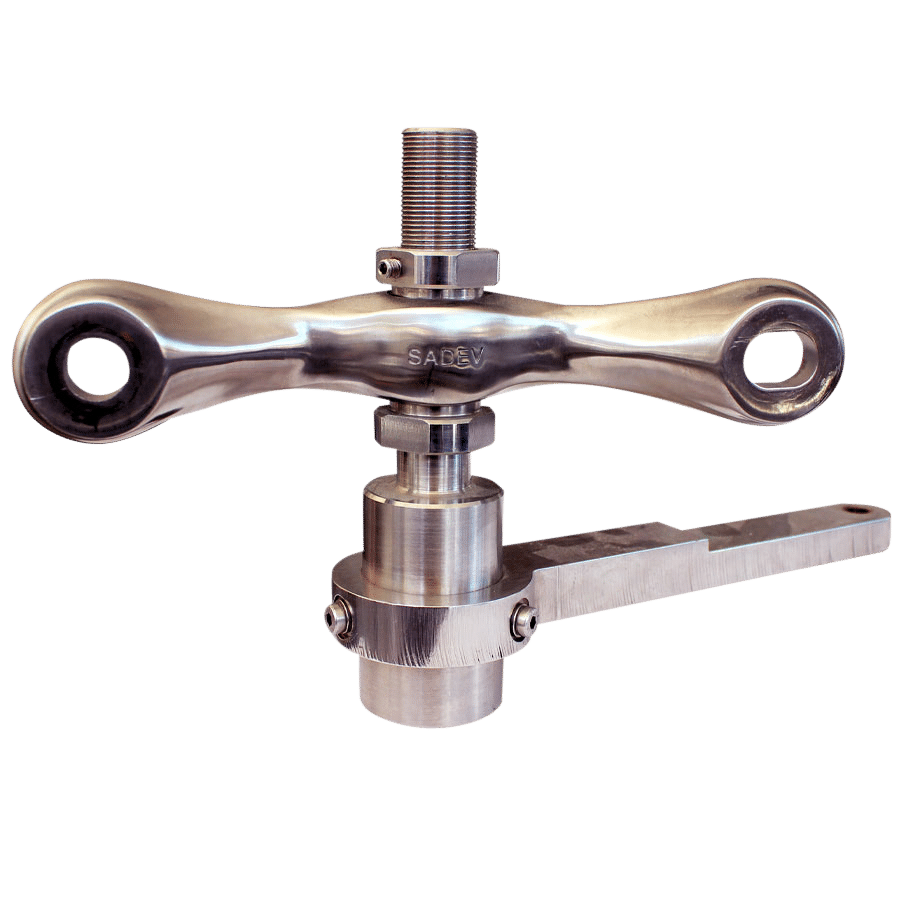

We manufacture your custom parts, using our engineering (in-house design office) and production (mechanical, casting capabilities).

Three approaches:

- We manufacture according to your plans, all parts in stainless steel and aluminium.

- We optimize your solutions based on your plans in manufacturing method ( economical)

- We design and manufacture according to your specifications or those established together see below.

PROJECT DESIGN AND MONITORING PROCESS

specialised methods office

specialised methods office

innovation at the heart of our development

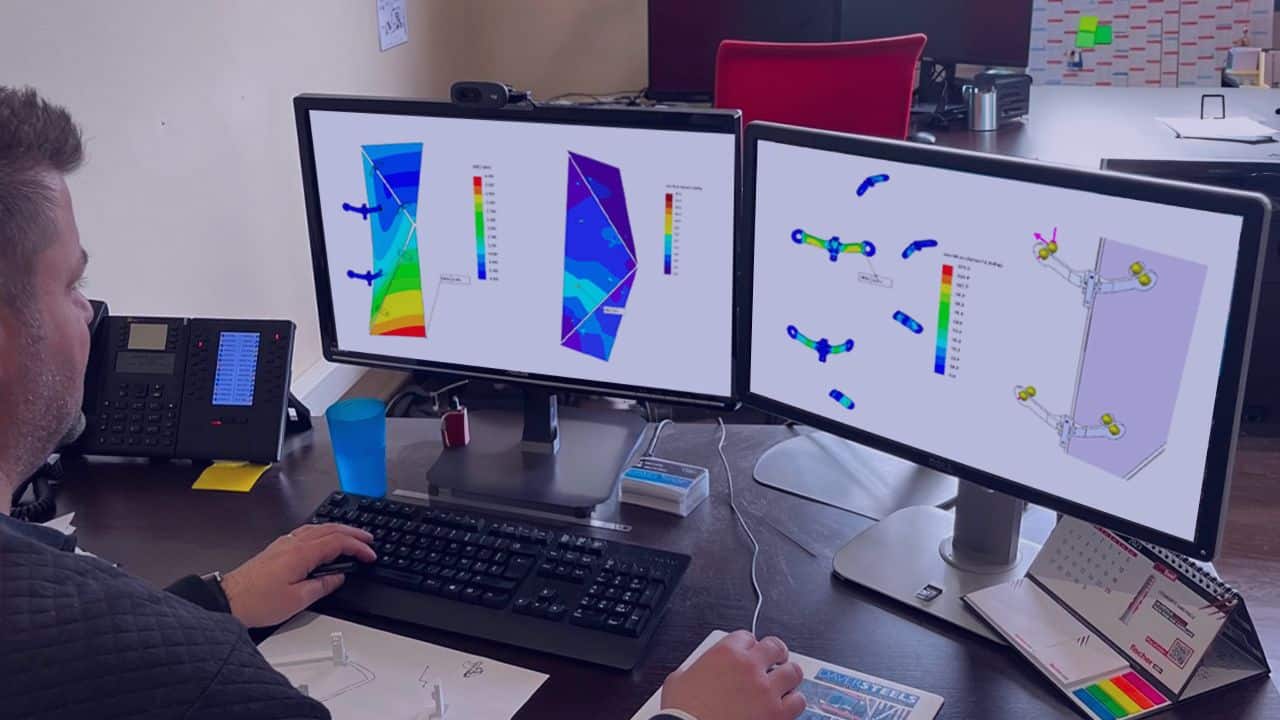

Much more than just an engineering firm, our methods department, consisting of experts in the field of glass and construction, advises and supports you in the execution of your projects, both in terms of design and in determining the manufacturing process. This dual expertise is a real asset to provide you with personalized support throughout the entire process, offering advice tailored to your needs in technical, aesthetic, and budgetary aspects.

Safety is a fundamental

All technical constraints are taken into account (including climate, environmental, and material constraints) for a reliable and optimized project. Our engineering team ensures the feasibility of your projects through calculations, various certifications, and technical assessments tailored to your specific requirements.

RESEARCH AND DEVELOPMENT

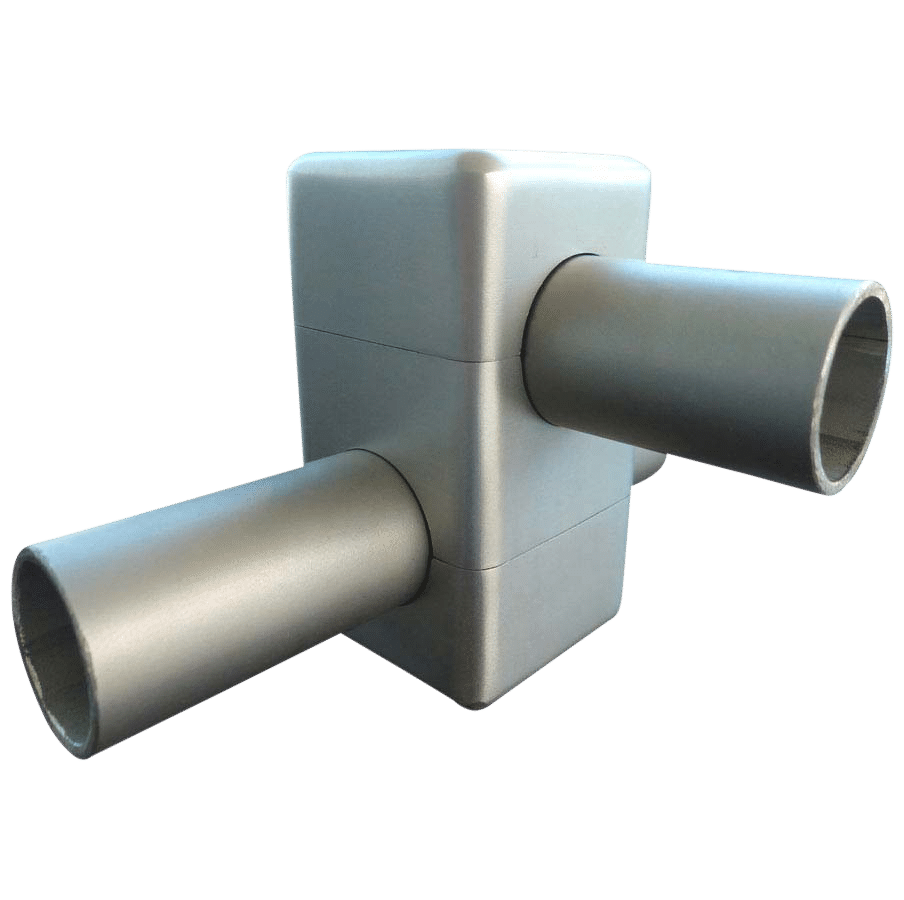

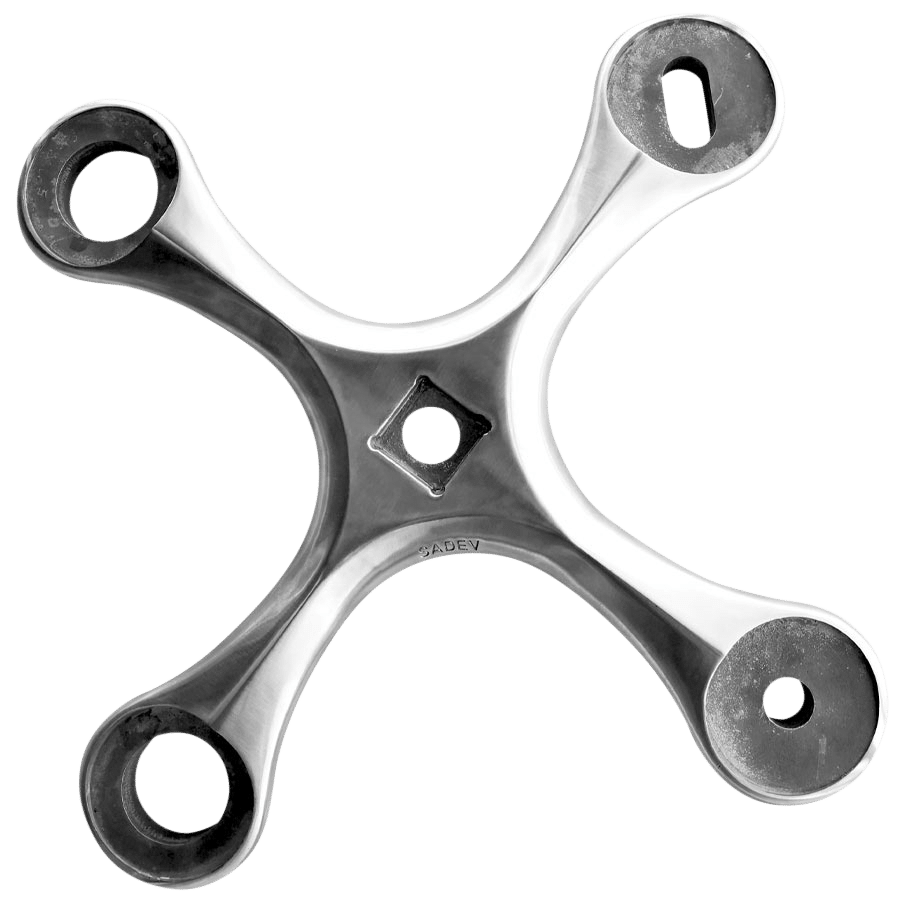

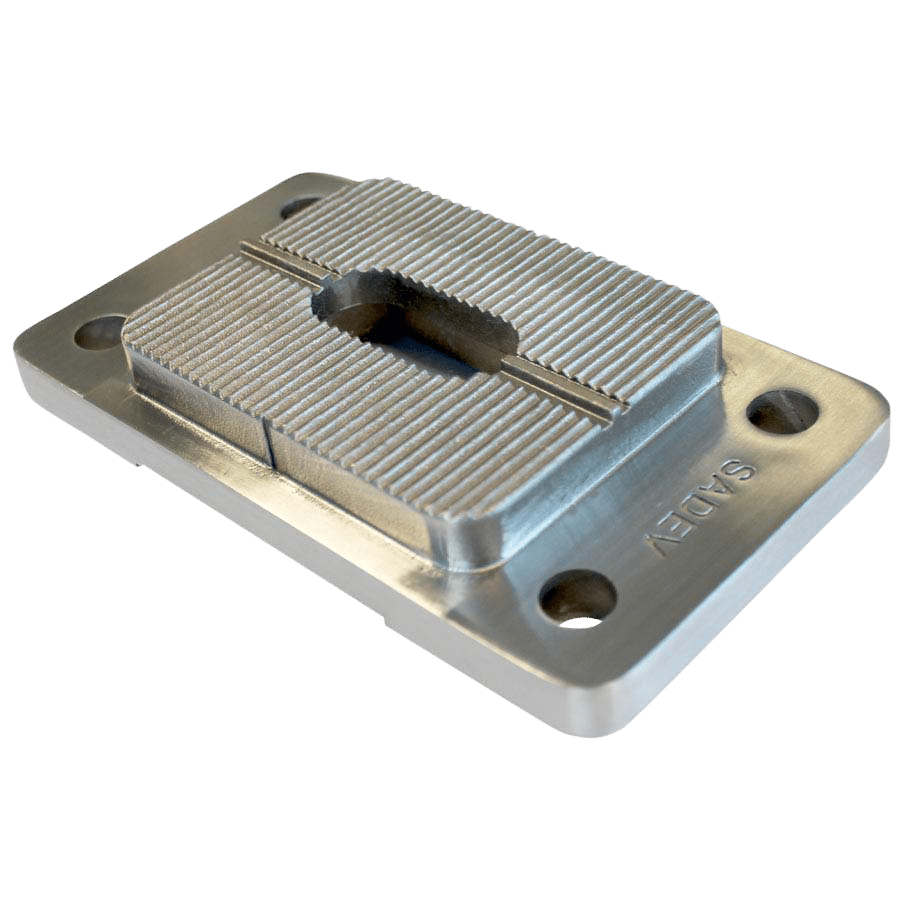

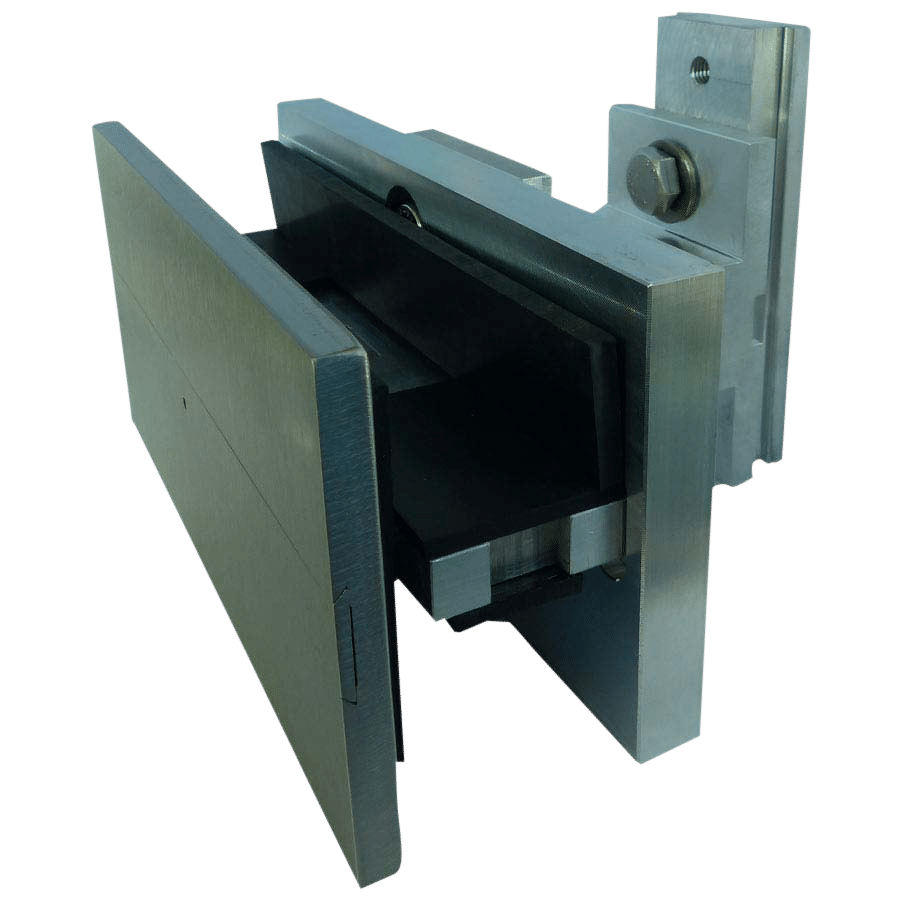

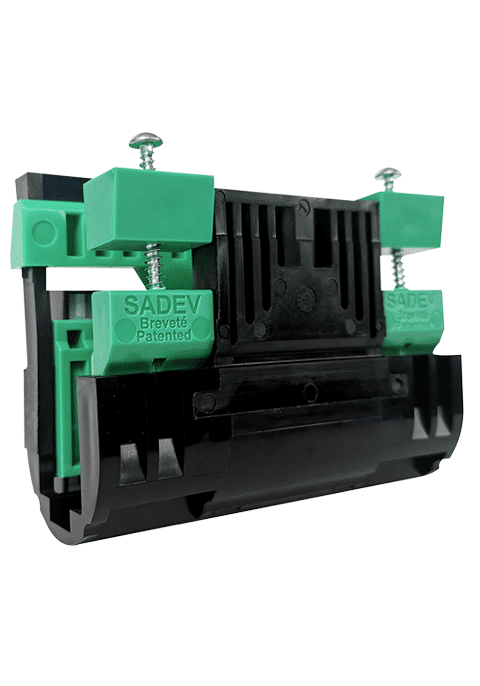

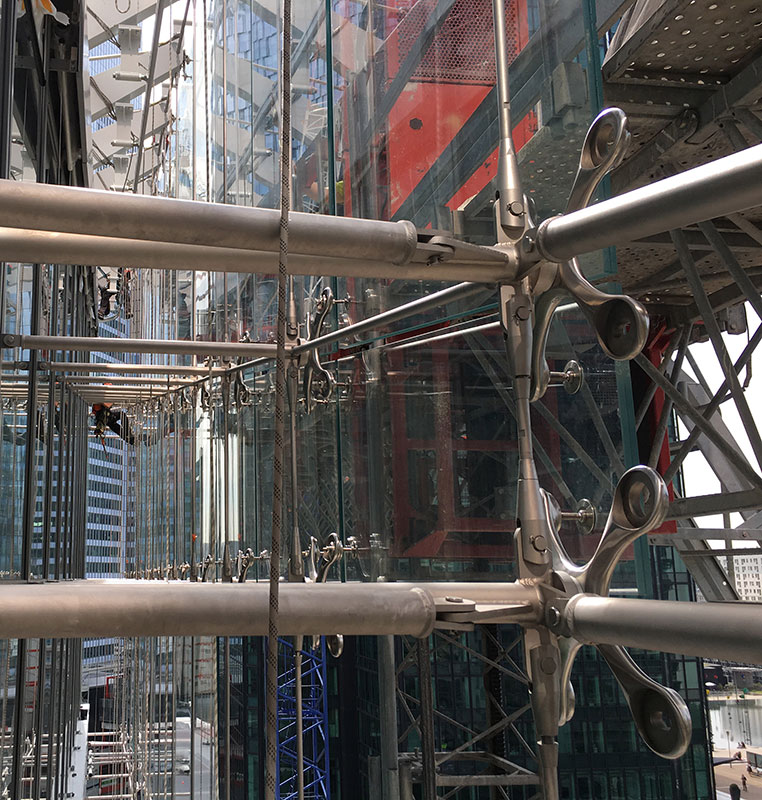

Thanks to this CONSTRUCT range, the implementation of materials such as glass, ultra-high performance concrete (UHPC) or any other building material is made possible.

All this is made possible by our mastery of the manufacture of castings in Stainless steel 304, 316, Duplex or aluminium, as well as in ABS plastic.

Our constant monitoring of new processes and new trends combined with your innovation of tomorrow’s architecture allows us to create unique pieces that meet the specifications of your project.

Our only limit is your imagination.

MANUFACTURING CONTROL

With our knowledge of the manufacturing process in foundry (lost wax for stainless steel and shell for aluminium) and other manufacturing processes.

We are able to offer you the best quality/price ratio by choosing the process adapted to the particularities of your parts, thus allowing you to optimise your manufacturing lead times and costs.

You offer you the most efficient solutions for the design of your parts.

Our 3D printer allows us to create the first prototype as soon as the 3D modeling is completed.

In addition, our machine park, mainly made up of the latest generation numerical controls (numerical lathe, palletized machining center, 30T assembly press, welding station…) is dedicated to the production of small or large series of stainless steel and aluminum parts.

Constant maintenance of our production tools coupled with the rigorous quality control applied to our parts have forged the know-how and reputation of our company.

INTERNATIONAL QUALITY CERTIFICATION

Tested and approved

Our adapted parts can be subjected to tests carried out in COFRAC approved laboratories and national laboratories to evaluate their durability, mechanical performance, thermal performance, reactions and fire resistance.

Each test is carried out according to references based on your specifications or on the regulatory texts of the country.

These tests, grouped together in a test report, can lead to the issue of a classification report or product certification.

TECHNICAL SUPPORT

We accompany you technically, right up to your site.

Our technical teams are at your service throughout the follow-up of your project, from the technical study to the installation on site.

They are at your disposal for:

– Understanding your project and providing you with technical advice

– Adjustment of parts during production

– On-site assistance in the form of installation training

THEY TRUST US

And you?

Let’s create a tailor-made solution for your project together.