Do you have a project in progress and want to optimise the costs of your parts, glass, assembly, production or product sizing?

Do you have a project in progress and want to optimise the costs of your parts, glass, assembly, production or product sizing?

SADEV has the solution

Designing your bespoke building components is a complex process that requires careful planning, creative design and efficient management. By taking into account the specific needs of the customer and the architects, while complying with quality and safety standards, it is possible to create made-to-measure solutions that fully meet the expectations and requirements of each construction project.

Quality

Guarantee a continuous improvement process for each service and ensure the reliability of our products as well as their compliance with current regulations and standards. Product quality is controlled in-house.

Flexibility

Adopting more flexible and modular production methods makes it easier to adapt to variations in demand and new market requirements. Our experience enables us to anticipate market trends.

Profitability

Optimise production costs by reducing raw material costs and minimising waste and scrap. Increase productivity by optimising the use of resources (labour, lead times, equipment, energy, etc.).

Innovation

Encourage innovation by enabling the introduction of new technologies, materials or processes to improve product design and production efficiency.

I have a project

I have a project

from design to prototype: our process

An insurance policy and professional liability coverage for the engineering firm are established from the outset of your custom project’s design.

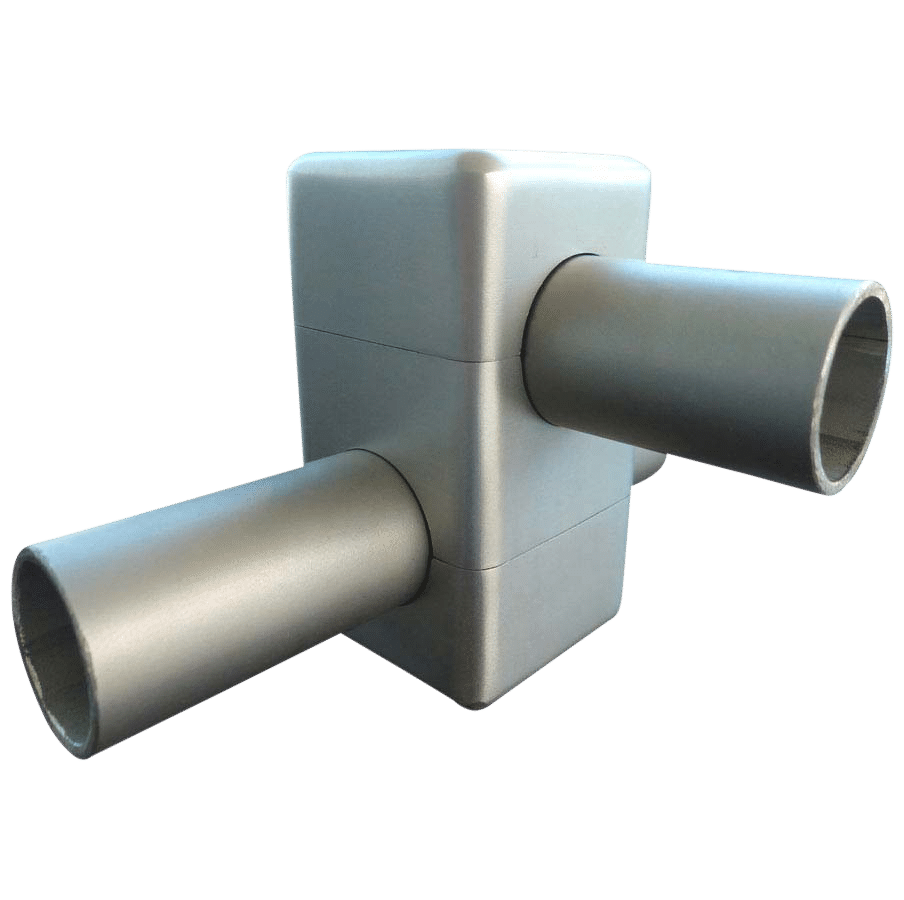

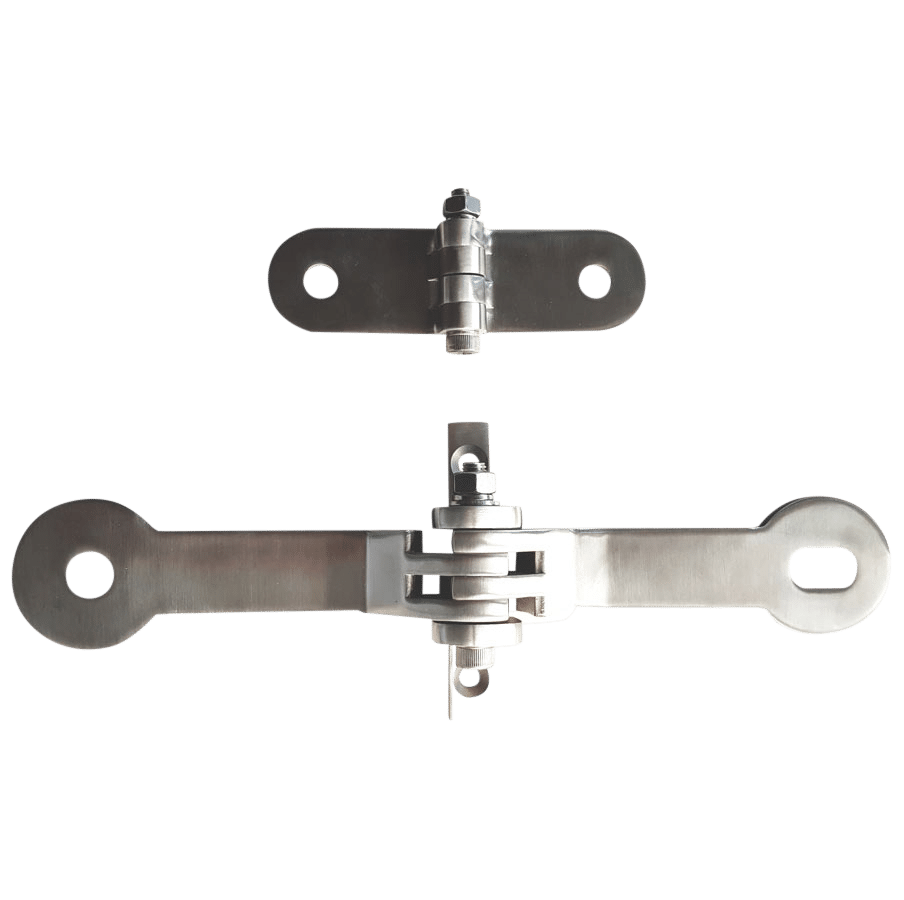

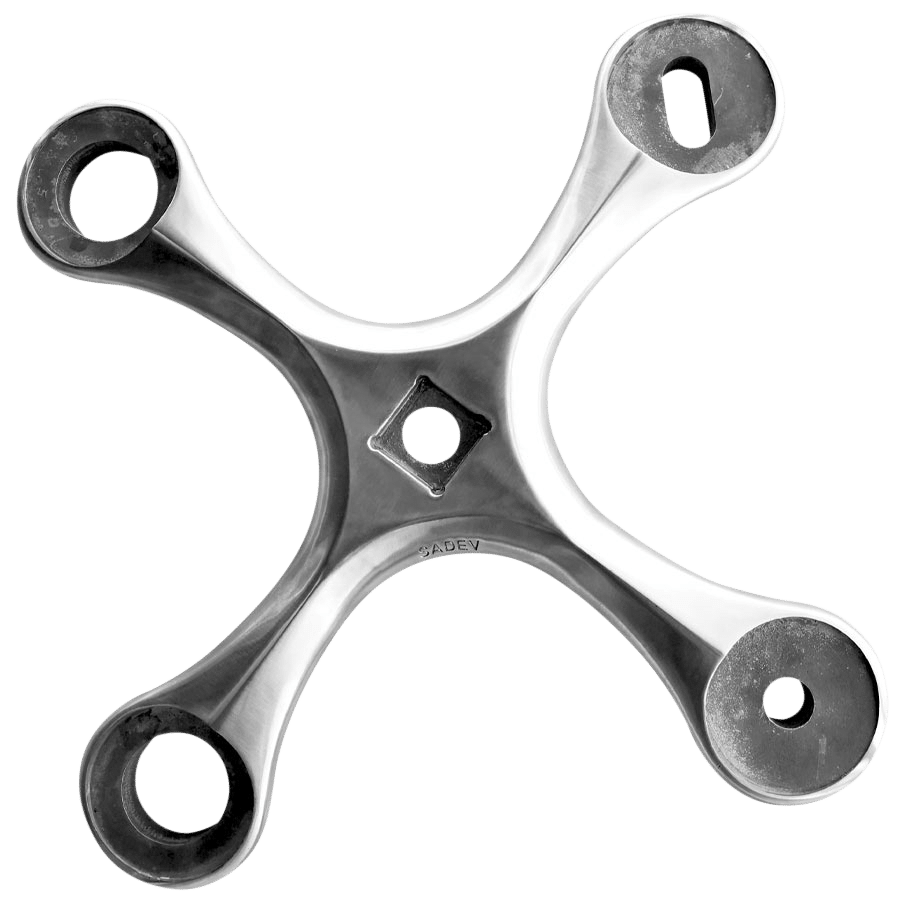

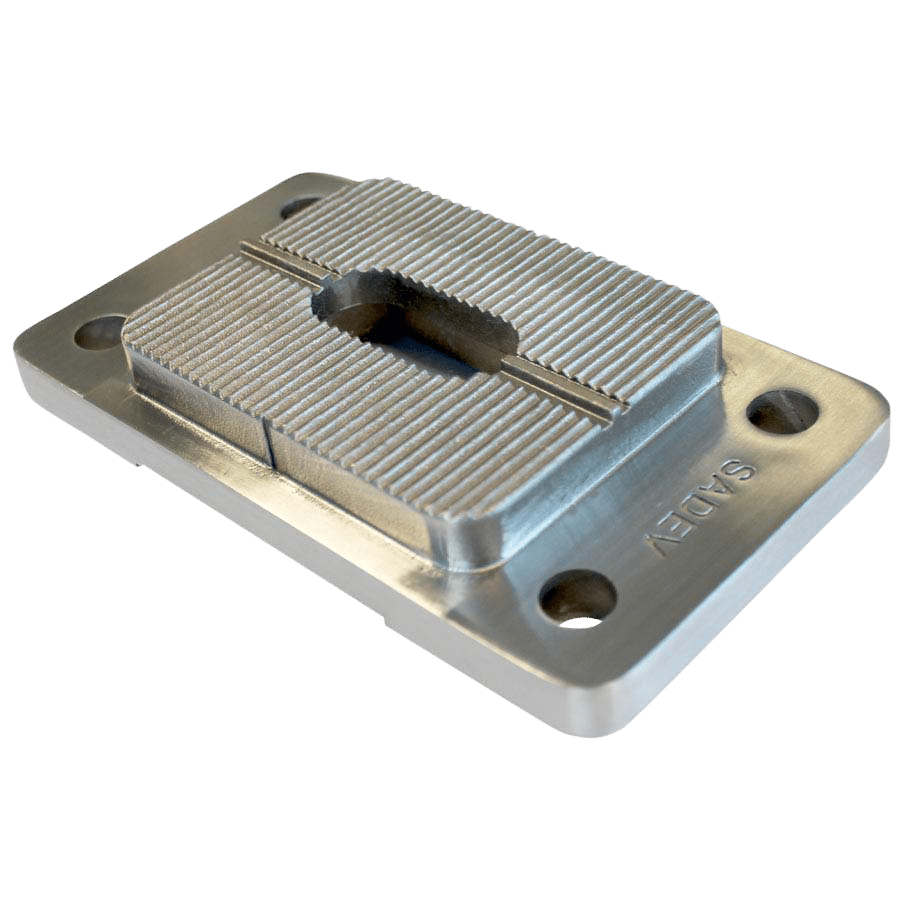

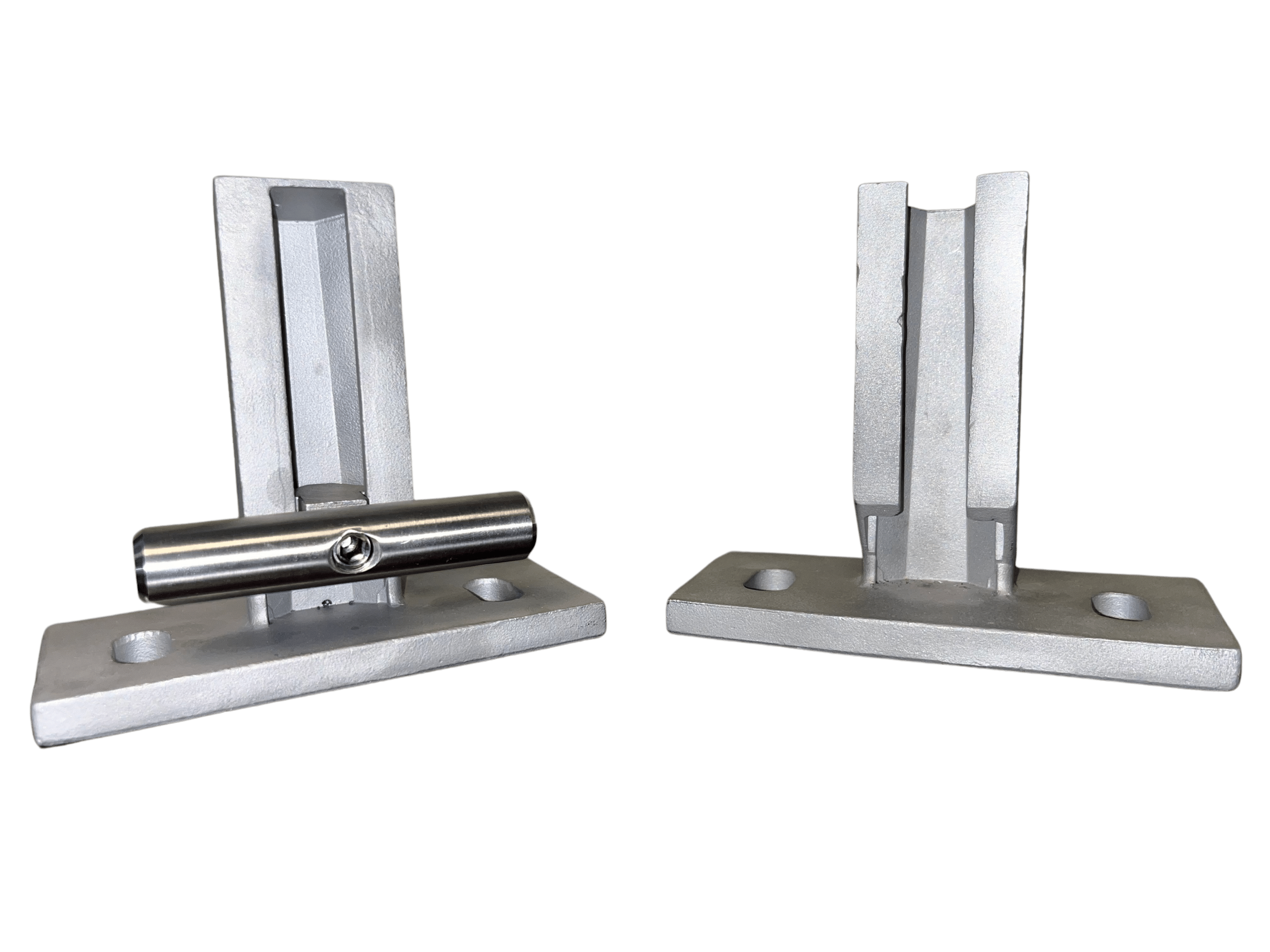

Our manufacturing methods allow us to produce unique shapes or particular geometries.

from design to prototype: our process

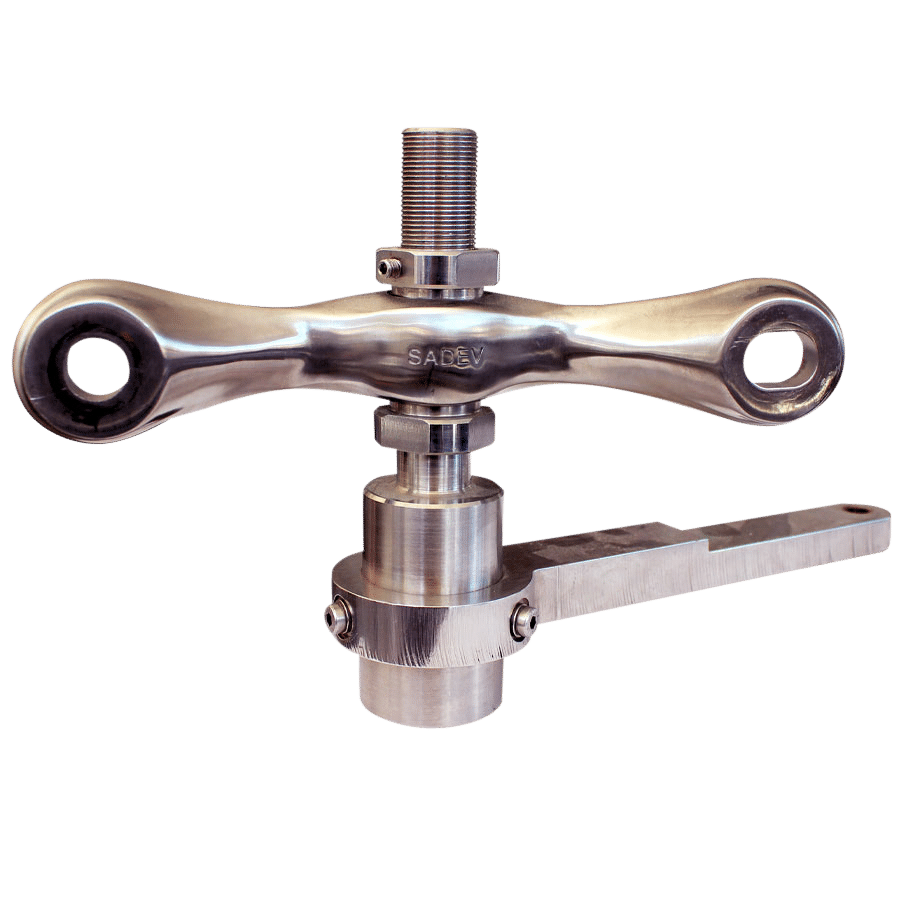

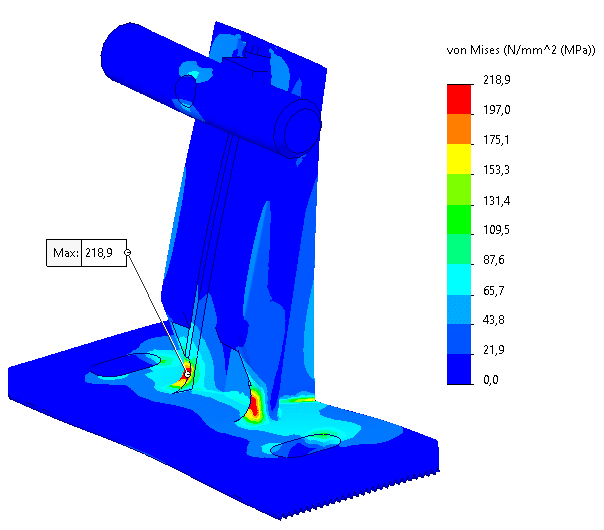

Understanding the properties of the materials used in glass fasteners is essential to ensure the safety and durability of glass structures.

By analysing the strength of materials, we can determine the maximum load that a glass structure can withstand before breaking. It also enables us to understand how the materials used react to stress.

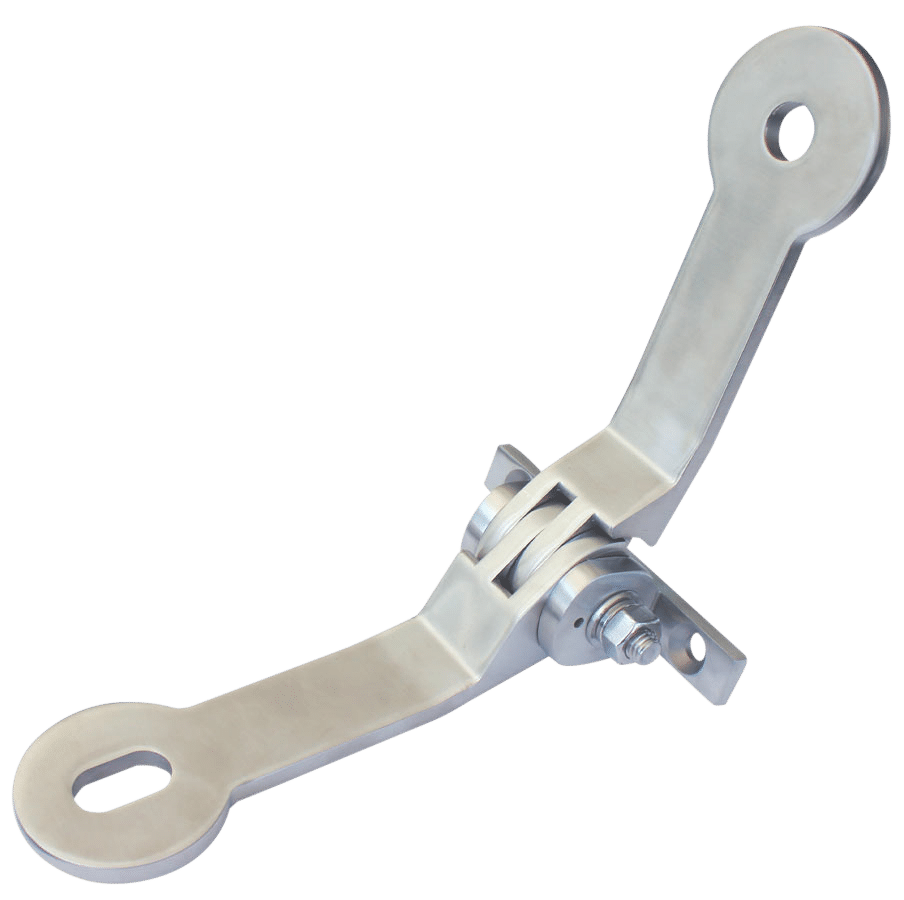

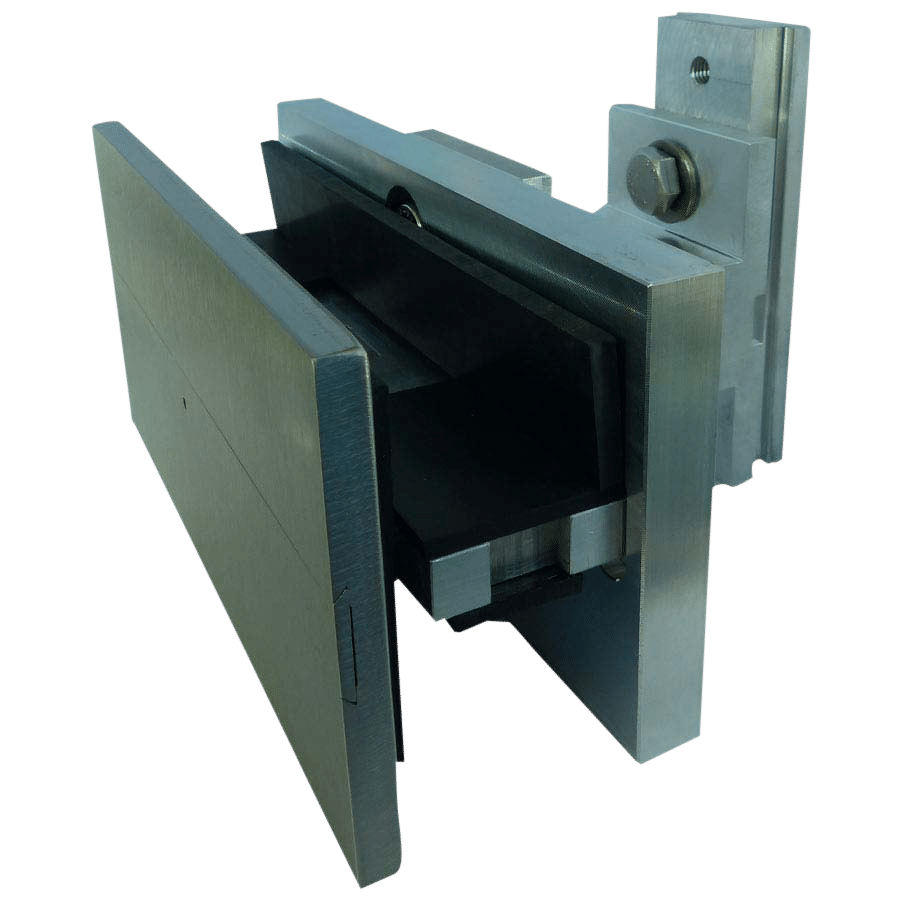

Example of a part optimisation for the fixing of a glazed facade with our customer COVERIS.

These materials are infinitely recyclable and have particularly good properties for fixing glass and for the environment.

Optimised solutions from sadev

1. We manufacture all parts in stainless steel, aluminium and all other materials to your drawings.

2. We adapt your solutions to our manufacturing methods to optimise the financial package.

3. We design and manufacture according to your specifications or those established together.

Creation of your 3d printing prototypes

Thanks to our engenieering departmentent, we can produce lead your project from item design to the finished product efficiently using 3D prototypes of part drawings.

Allowing you to have a physical rendering of what the part will be like, before machining, is an essential asset for optimizing your products. You can get prototypes for all your projects.

STAY INFORMED!

Technician’s blog

SADEV – The importance of glass in the building industry energy transition

Considered primarily as a window material, glass has evolved to become an essential element of modern architecture. Its use in construction offers a multitude of functional and aesthetic advantages, contributing to the creation of iconic structures around the world....

SADEV – The benefits of glass railings

SADEV glass balustrades come to your home!According to a survey by INPES (the French national institute for health prevention and education) published in March 2014, 49% of accidental falls by children take place even though the opening had protection. This research...

SADEV – French railing legislation

INTRODUCTION Guardrails play a crucial role in the safety of elevated spaces, whether on balconies, terraces, stairs, or roofs. Guardrails, or balustrades, aim to prevent the risk of falling and ensure the protection of individuals. There are different types of...

THEY TRUST US