“Our expertise, your savings”

We are specialise in the design of tailor-made fasteners for your projects

“Our expertise, your savings”

We are specialise in the design of tailor-made fasteners for your projects

An architectural project?

Need a specific fastener?

SADEV handles the design

or its optimisation

– Lower costs for the customer

– Guaranteed safety and viability

STEPS FOR CREATING A TAILOR-MADE PRODUCT

STEPS FOR CREATING A TAILOR-MADE PRODUCT

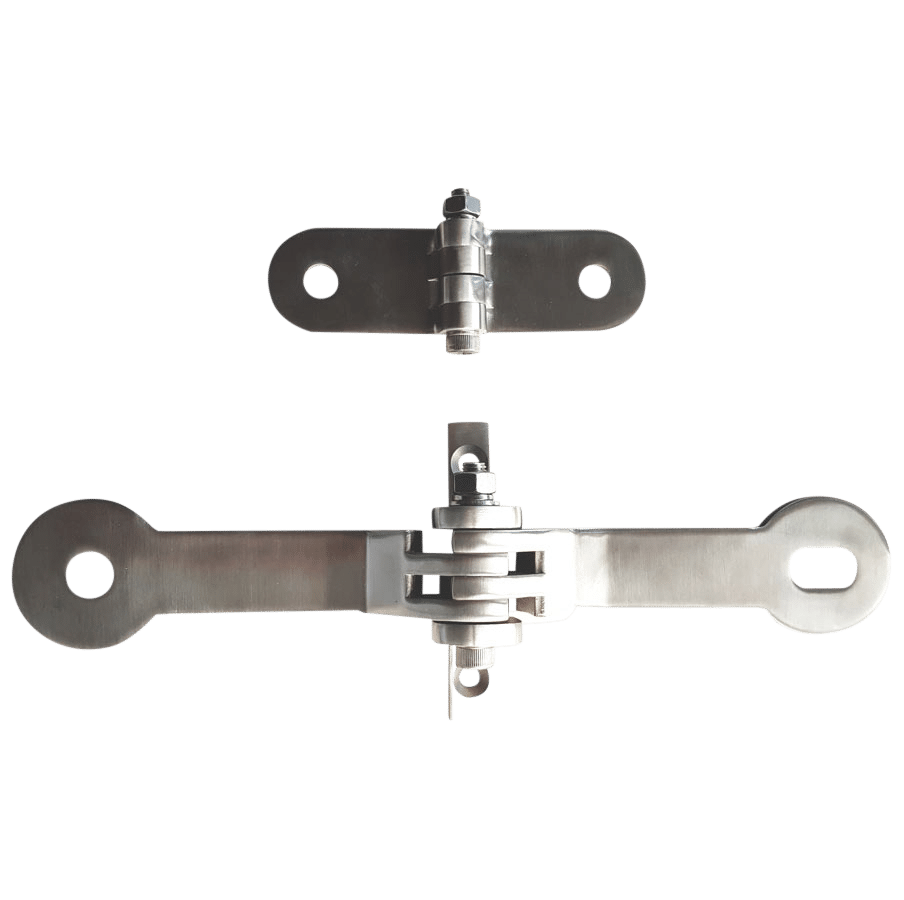

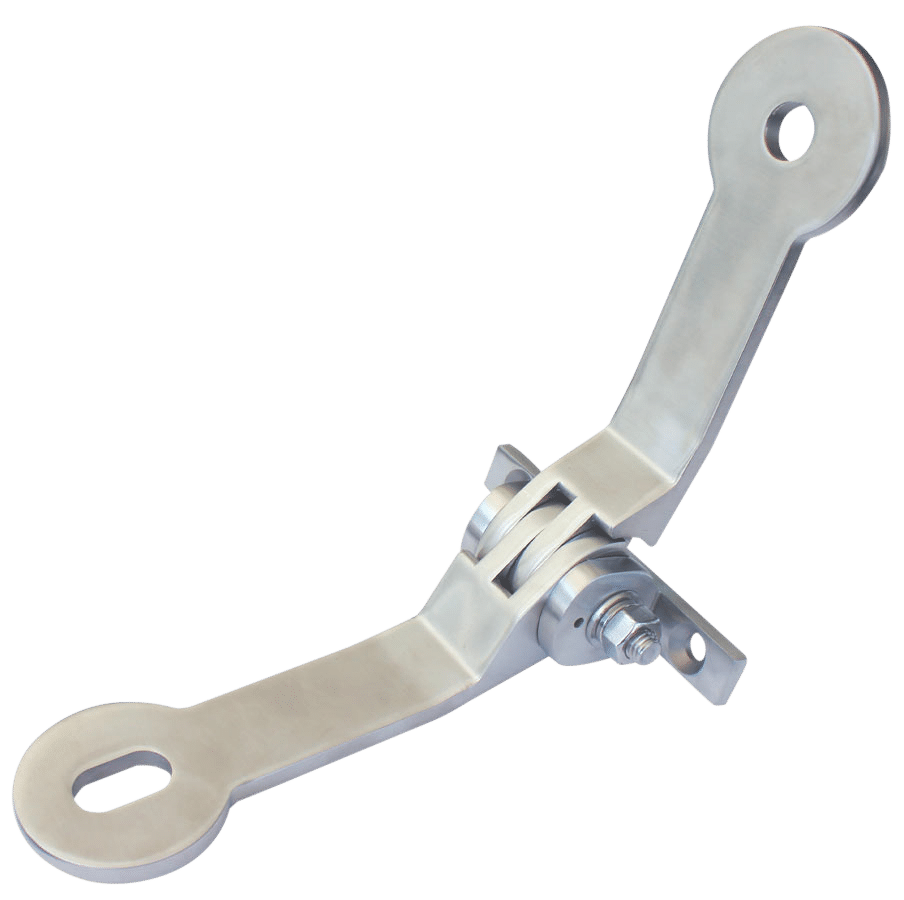

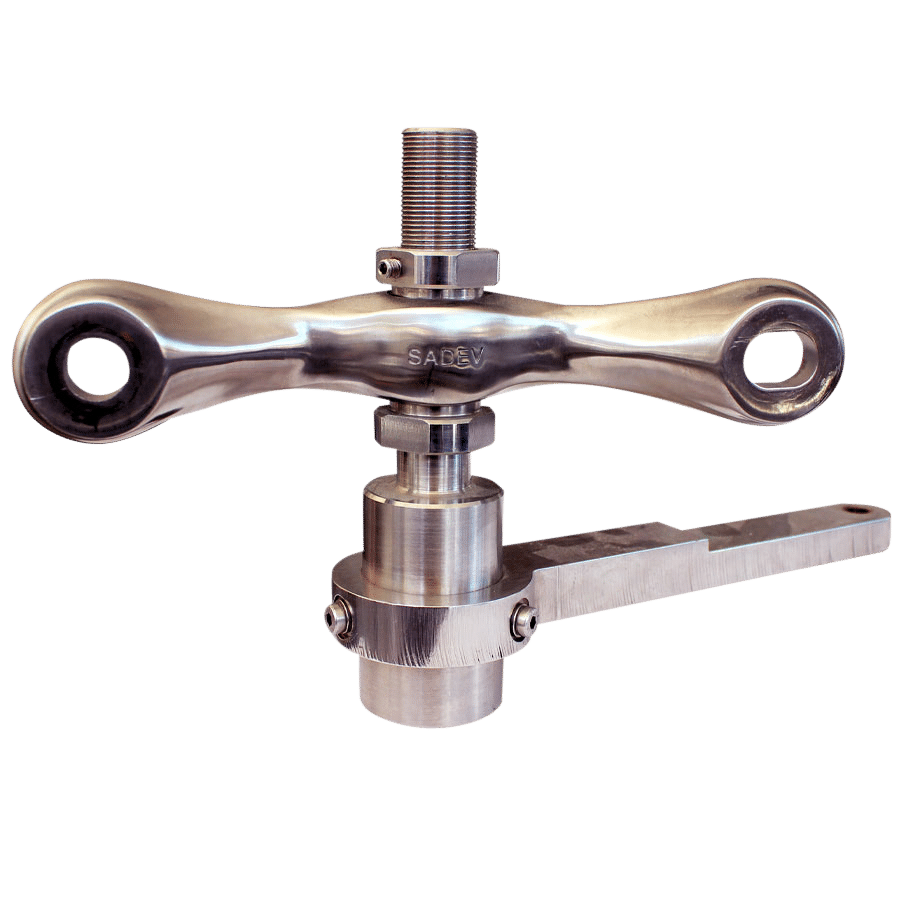

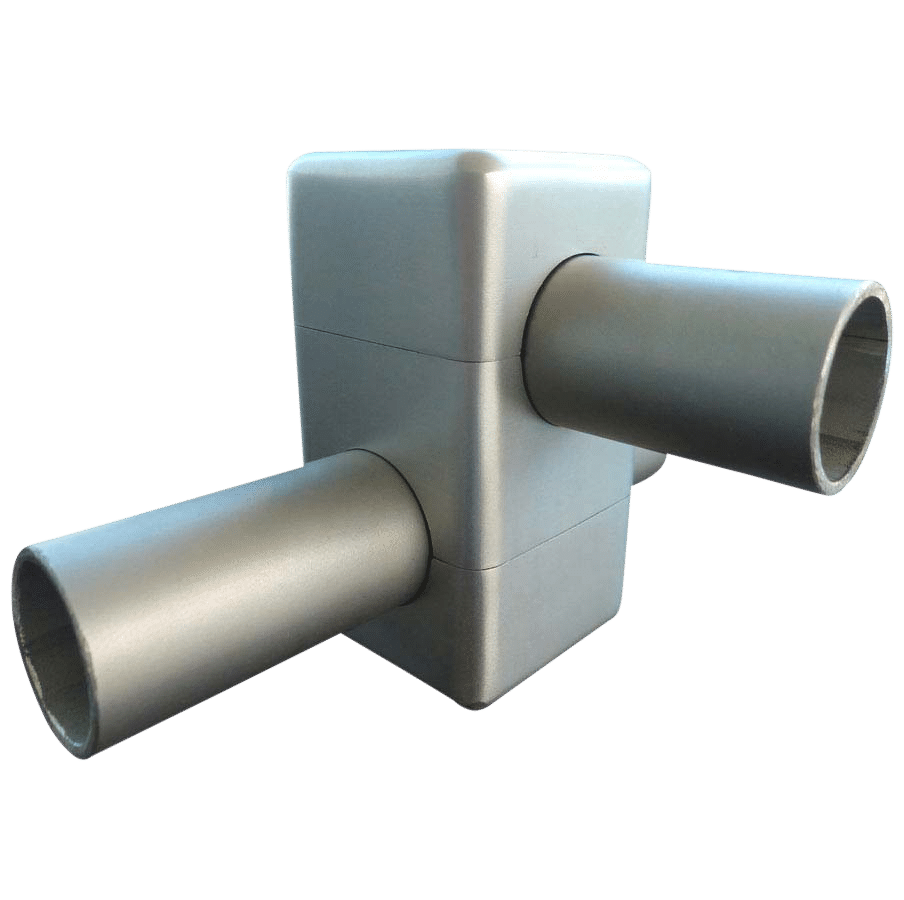

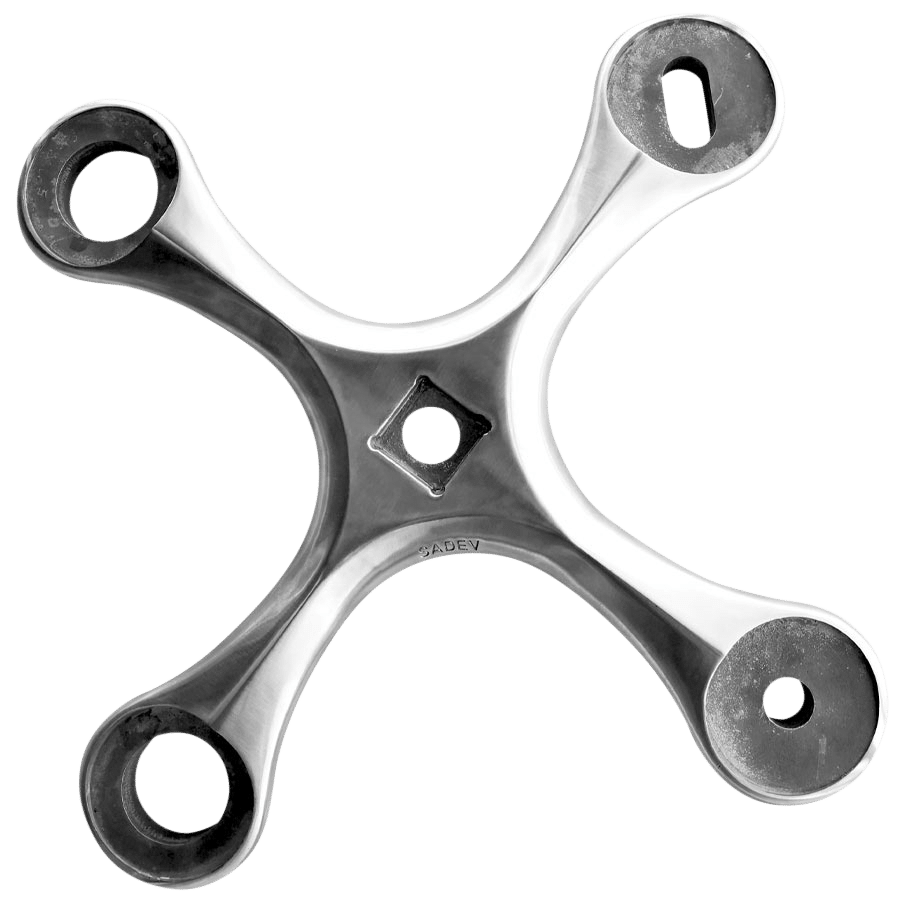

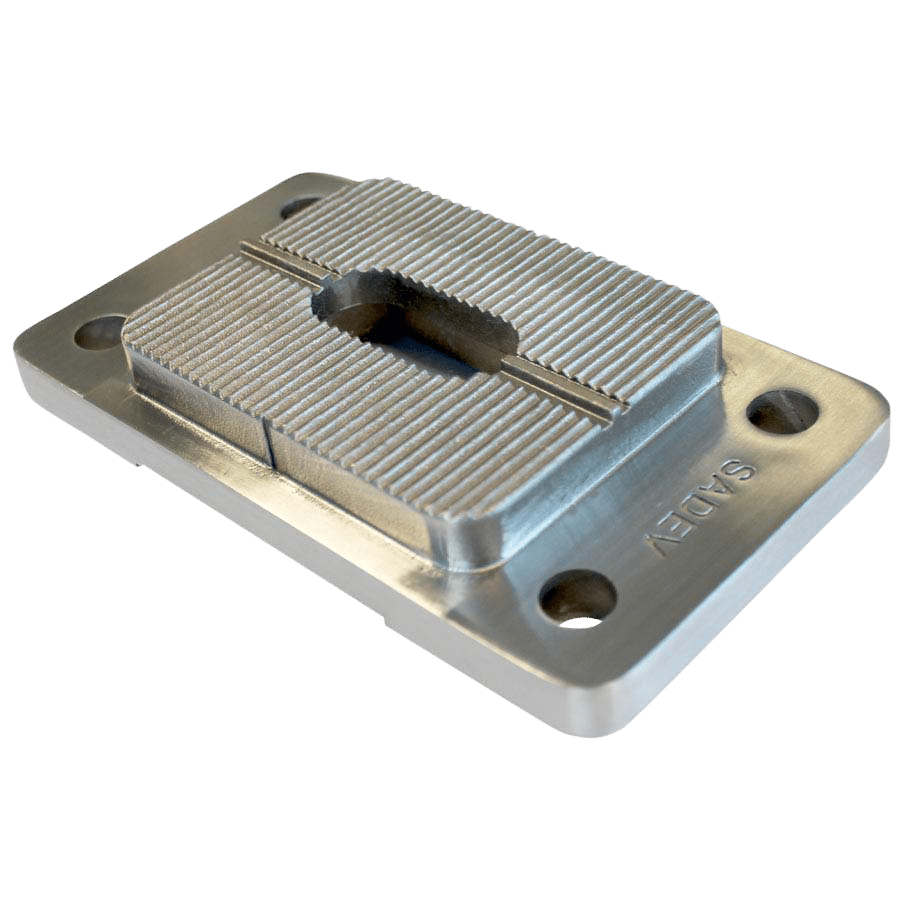

TAILOR-MADE PARTS FOR YOUR PROJECT

TAILOR-MADE PARTS FOR YOUR PROJECT

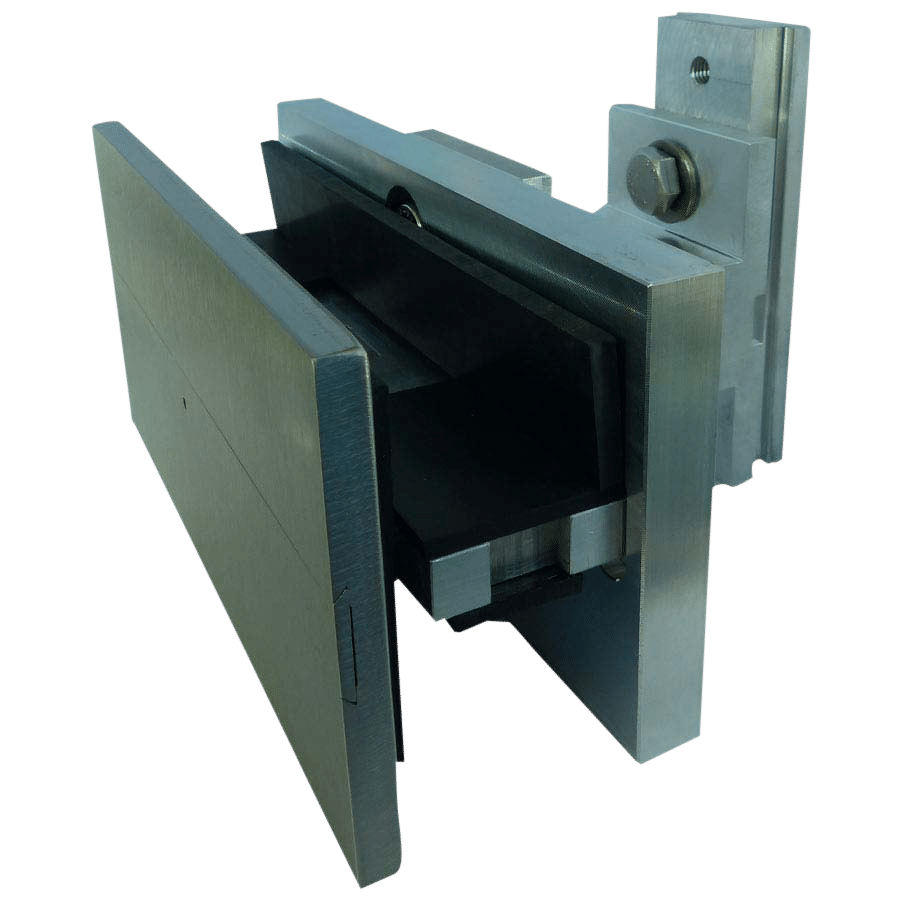

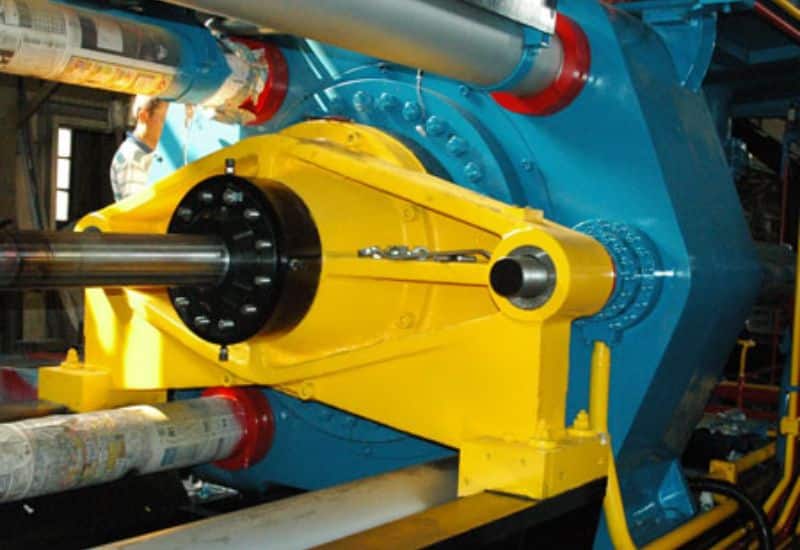

Thanks to our engineering and production capabilities, we can manufacture your customised parts.

1. We manufacture all parts in stainless steel, aluminium and all other materials to your drawings.

2. We adapt your solutions to our manufacturing methods to optimise the financial package.

3. We design and manufacture according to your specifications or those established together.

CONTROLLING PRODUCTION

CONTROLLING PRODUCTION

Cost control

Control of resources

Quality control

Custom machining

Moulding and casting

Aluminium extrusion

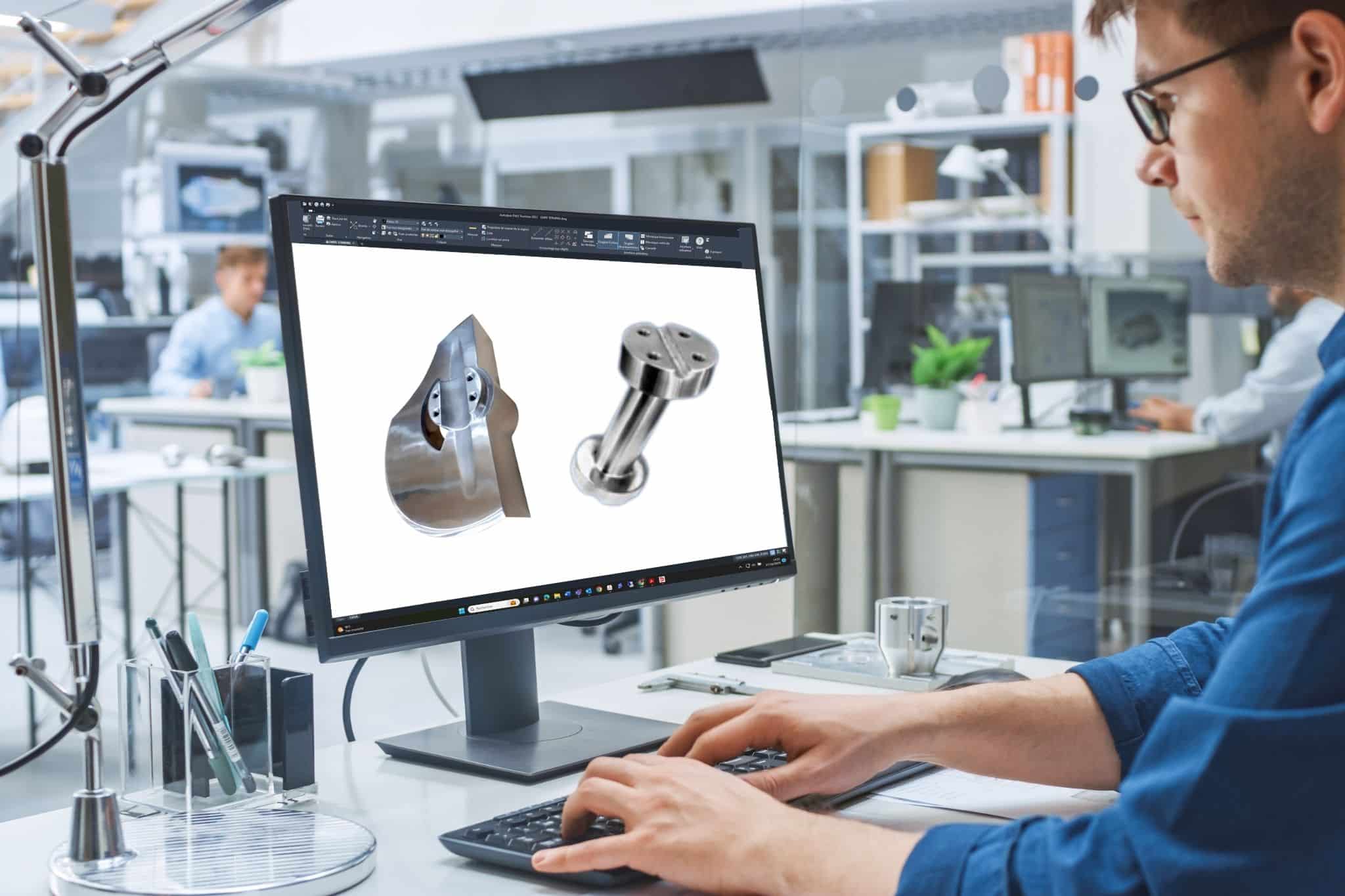

Creation of your 3d printing prototypes

Creation of your 3d printing prototypes

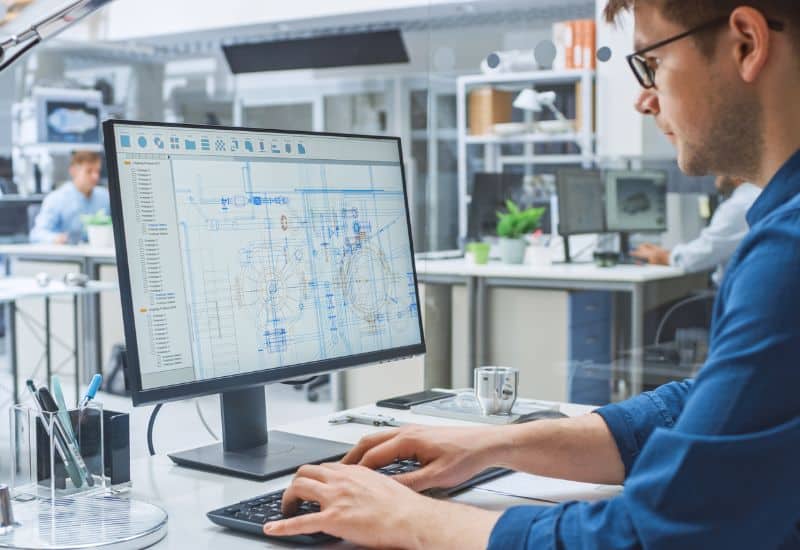

Thanks to our engenieering departmentent, we can produce lead your project from item design to the finished product efficiently using 3D prototypes of part drawings.

Allowing you to have a physical rendering of what the part will be like, before machining, is an essential asset for optimizing your products.

You can get prototypes for all your projects.

TEST MANAGEMENT

TEST MANAGEMENT

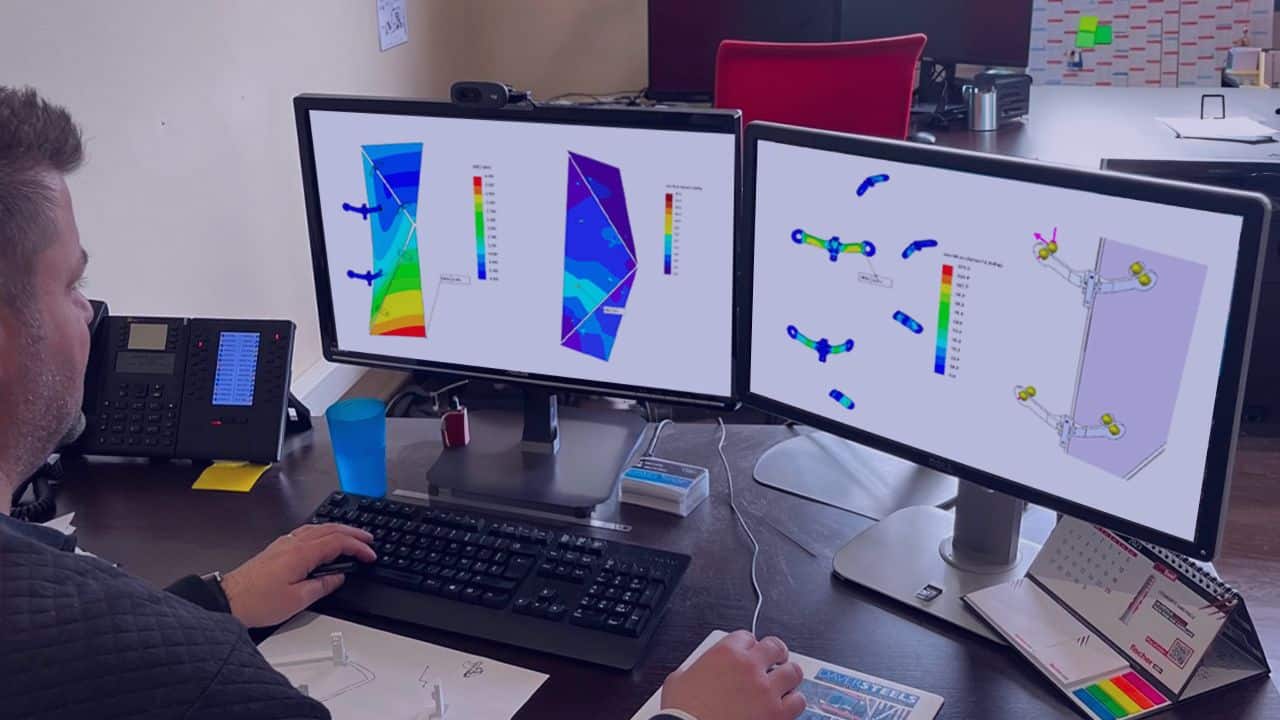

Following the completion of a calculation note, tests may be conducted to optimize and validate the fastening components according to the standards of each country.

SADEV manages all testing either in-house through its “SADEV LAB” or externally with accredited specialized laboratories. Validation tests must be carried out to ensure that the designs meet performance, quality, and durability standards in accordance with the requirements of the countries involved.

We conduct your ATEx for all types of projects in France.

specialised methods office

specialised methods office

innovation at the heart of our development

Much more than just an engineering firm, our methods department, consisting of experts in the field of glass and construction, advises and supports you in the execution of your projects, both in terms of design and in determining the manufacturing process. This dual expertise is a real asset to provide you with personalized support throughout the entire process, offering advice tailored to your needs in technical, aesthetic, and budgetary aspects.

Safety is a fundamental

All technical constraints are taken into account (including climate, environmental, and material constraints) for a reliable and optimized project. Our engineering team ensures the feasibility of your projects through calculations, various certifications, and technical assessments tailored to your specific requirements.

Discover all our made-to-measure projects

Discover all our made-to-measure projects

All types of building

STAY INFORMED!

Technician’s blog

SADEV – The importance of glass in the building industry energy transition

Considered primarily as a window material, glass has evolved to become an essential element of modern architecture. Its use in construction offers a multitude of functional and aesthetic advantages, contributing to the creation of iconic structures around the world....

SADEV – The benefits of glass railings

SADEV glass balustrades come to your home!According to a survey by INPES (the French national institute for health prevention and education) published in March 2014, 49% of accidental falls by children take place even though the opening had protection. This research...

SADEV – French railing legislation

INTRODUCTION Guardrails play a crucial role in the safety of elevated spaces, whether on balconies, terraces, stairs, or roofs. Guardrails, or balustrades, aim to prevent the risk of falling and ensure the protection of individuals. There are different types of...

THEY TRUST US