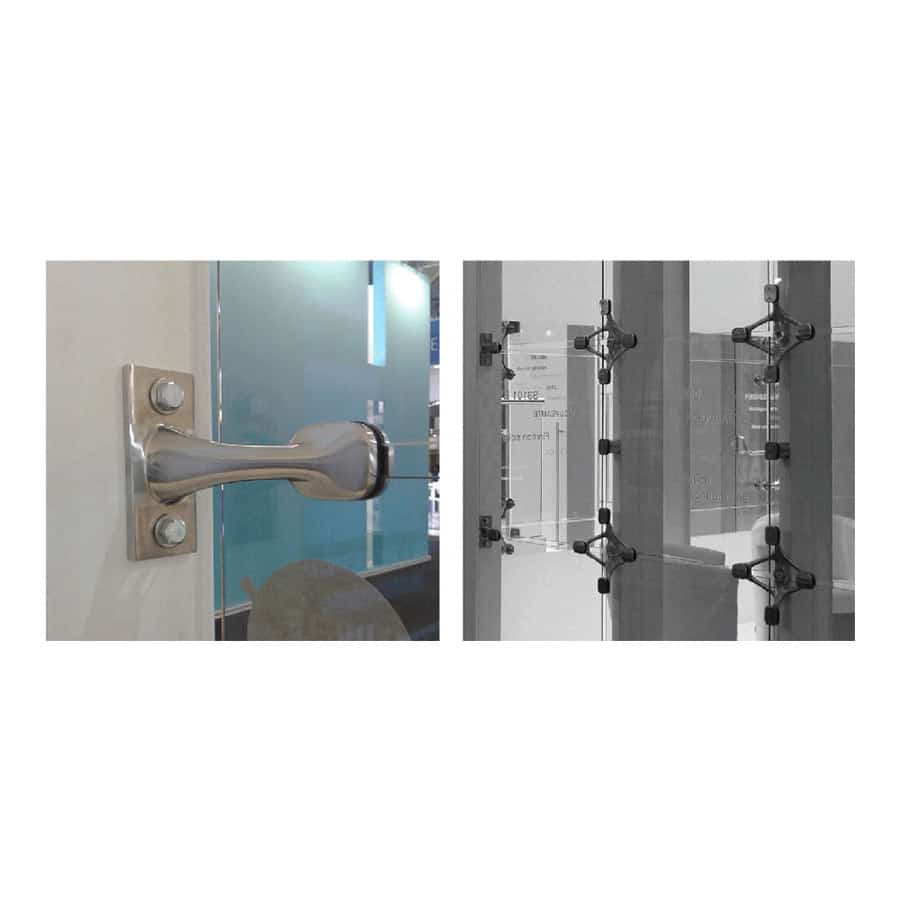

- Economical: no drilling & easy to install

- Suitable for any type of glass composition

- Innovative solution

- Insulating glazing possible

Stainless steel clamp spider

Thanks to a new fixing process, glass panels are supported even in cases of heavy applied loads.

Requires no glass drilling, allowing easy and quick installation. Parts are made out of 316 Stainless steel with a brushed finish (standard) allowing installation in both interior and exterior environments and nearly any condition.

Full product range to meet the requests of all clamp façades projects

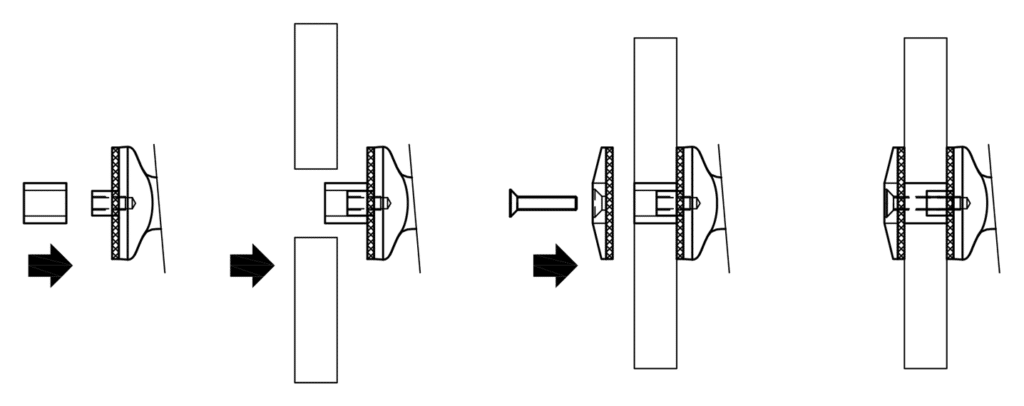

Suggested mounting

Mounting of the spiders on the structure

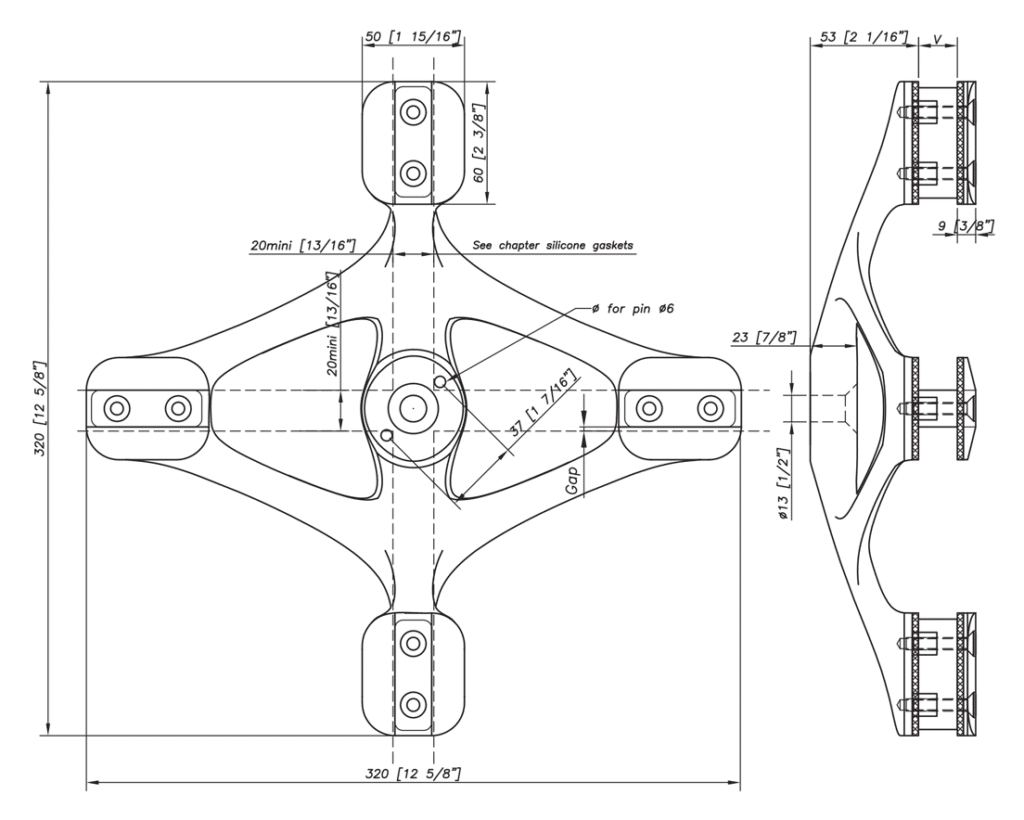

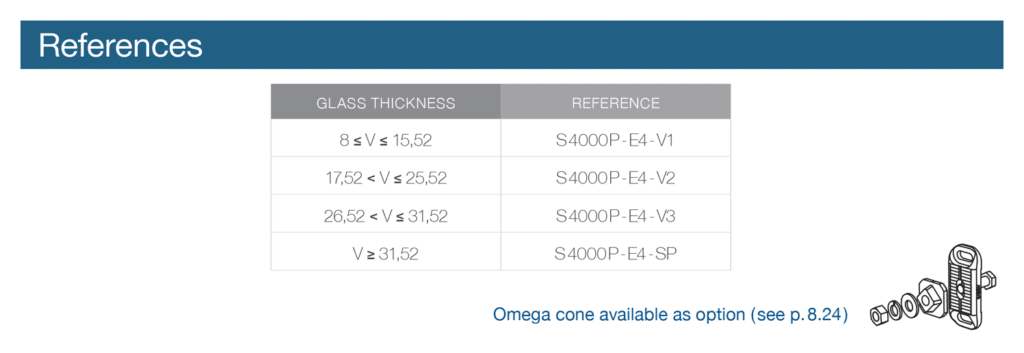

S4000P

If mounting directly to the structure anti-rotation pins are recommended to prevent the clamps from rotating. The diameter of the anti-rotation pins is 6 mm. Do not pre-drill the holes for the pins in your structure before mounting spiders. Drill bits and anti-rotation are provided.

An alternate attachment interface (Omega) is available. The Omega interface allows for vertical adjustment of the clamp fitting to account for tolerances in the drilling of the structural steel.

The fixing of the spider is done with a M12 (1/2 in.) Flat head screw (Not supplied by Sadev). A vertical slot in the structural steel for vertical adjustment is not recommended due to the high dead load weight of the glass.

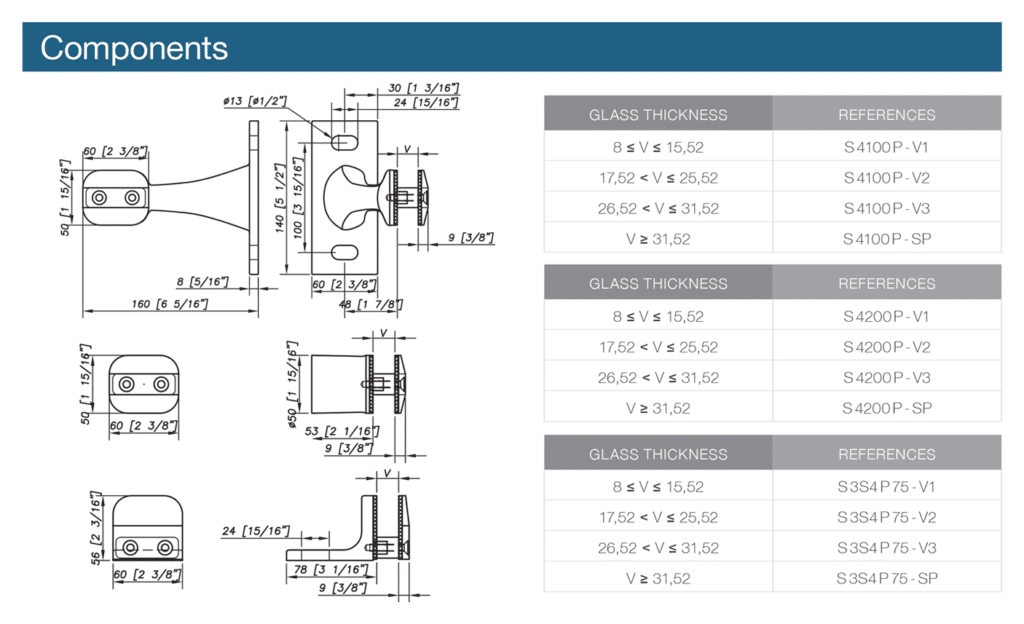

S4100P

Attaching the spider to the vertical fin or support is done with two M12 (1/2 in.) bolts (not supplied by Sadev).

S4200P / S3S4P75

The fixing of the single point clamp is done with one M12 bolts (Not supplied by Sadev).

Installing the glass

Mount the gravity shelf to the spider casting. Install the glass panel and secure with the external clamp plate using M6 screws provided. Torque both screws to 20 Nm (15 ft lbs) for monolithic glass and 10Nm (8 ft lbs) for laminated (PVB) glass.

We are pleased to present you the first edition of the SADEV Newspaper. Flip through…

View article

Our SADEV YouTube channel celebrates its 10K subscribers! THANK YOU You are now 10 000…

View article

We inform you that our SADEV Price list has been updated. The SADEV Price list…

View article

Our company will be closed from 25 December 2020 to 3 January 2021 included. Due…

View article

[French Lockdown –SADEV’s situation] What is the current situation of COVID in France? « Starting…

View article

SADEV at BAU exhibition, Munich BAU is one of the World’s Leading Trade Fair for…

View article

SEISMIC VALIDATION – TECHNICAL ASSESSMENT The laws and regulations on earthquake-resistant construction have evolved in…

View article

With the increase in terrorist attacks, the protection of people and property within public infrastructure…

View article

Get ready to discover our latest news at BATIMAT BATIMAT exhibition, which will take place…

View article

A new facade system for structural glazing with a unique aesthetic design incorporating gentle curves…

View article

GLASS FORUM – Glass as an architectural solution Meet our teams in Spain for a…

View article

We are pleased to confirm our presence at BAU again this year! 📣 The world’s…

View article

SADEV will be present at this new edition of the Mondial du Bâtiment from September…

View article

Calculation methods for glass panels Moving the glazing under load (Service Limit State) GENERAL The…

View article

Dear customers, SADEV has been featured in the latest edition of the prestigious magazine ARCHI…

View article

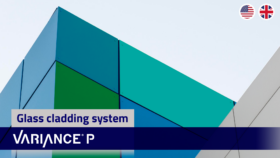

A revolutionary glass cladding system Discover the new glass cladding solution – Variance P In…

View article

Thermal expansion of facades with point fixed glazing system Introduction: In the field of construction,…

View article

We are excited to be part of the world’s leading trade fair for Architecture, Materials…

View article

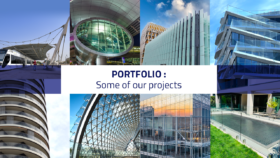

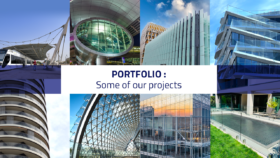

Discover some of SADEV’s projects over the last few years! https://youtu.be/4ZyehEXFvws

View article

BATIMAT – 03-06 October, PARIS – Porte de Versailles For SADEV, this edition is…

View article

POLYCLOSE – August 31, September 1 & 2, 2022 – BELGIUM “The European trade fair…

View article

All our team wishes you a Happy New Year! May this year 2022 bring…

View article

We are pleased to present you the first edition of the SADEV Newspaper. Flip through…

View article

Our SADEV YouTube channel celebrates its 10K subscribers! THANK YOU You are now 10 000…

View article

We inform you that our SADEV Price list has been updated. The SADEV Price list…

View article

Our company will be closed from 25 December 2020 to 3 January 2021 included. Due…

View article

[French Lockdown –SADEV’s situation] What is the current situation of COVID in France? « Starting…

View article

SADEV at BAU exhibition, Munich BAU is one of the World’s Leading Trade Fair for…

View article

SEISMIC VALIDATION – TECHNICAL ASSESSMENT The laws and regulations on earthquake-resistant construction have evolved in…

View article

With the increase in terrorist attacks, the protection of people and property within public infrastructure…

View article

Get ready to discover our latest news at BATIMAT BATIMAT exhibition, which will take place…

View article

A new facade system for structural glazing with a unique aesthetic design incorporating gentle curves…

View article

GLASS FORUM – Glass as an architectural solution Meet our teams in Spain for a…

View article

We are pleased to confirm our presence at BAU again this year! 📣 The world’s…

View article

SADEV will be present at this new edition of the Mondial du Bâtiment from September…

View article

Calculation methods for glass panels Moving the glazing under load (Service Limit State) GENERAL The…

View article

Dear customers, SADEV has been featured in the latest edition of the prestigious magazine ARCHI…

View article

A revolutionary glass cladding system Discover the new glass cladding solution – Variance P In…

View article

Thermal expansion of facades with point fixed glazing system Introduction: In the field of construction,…

View article

We are excited to be part of the world’s leading trade fair for Architecture, Materials…

View article

Discover some of SADEV’s projects over the last few years! https://youtu.be/4ZyehEXFvws

View article

BATIMAT – 03-06 October, PARIS – Porte de Versailles For SADEV, this edition is…

View article

POLYCLOSE – August 31, September 1 & 2, 2022 – BELGIUM “The European trade fair…

View article

All our team wishes you a Happy New Year! May this year 2022 bring…

View article