Swivel fitting - rotule - for structural bolted glass - Cylindrical head - not flush with glass - technical Evaluation - seismic option available - bomb blast resistant

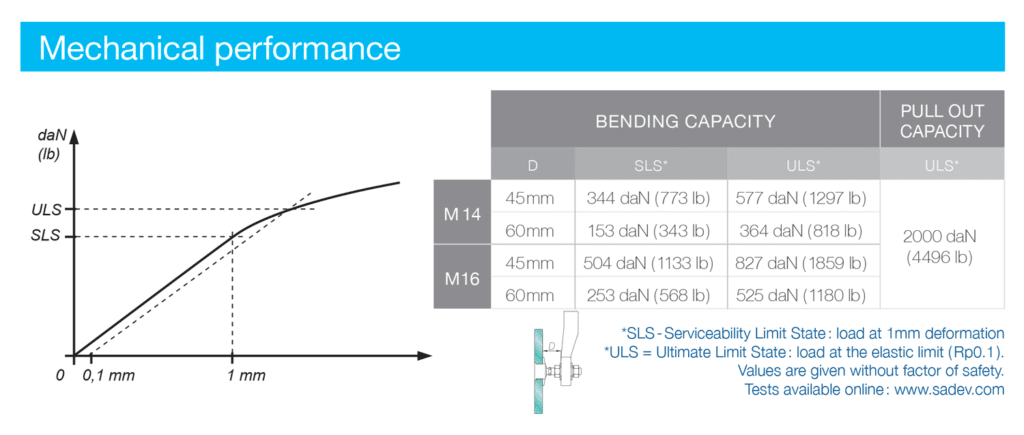

High mechanical performance

- Tested and certified by technical evaluation (test report)

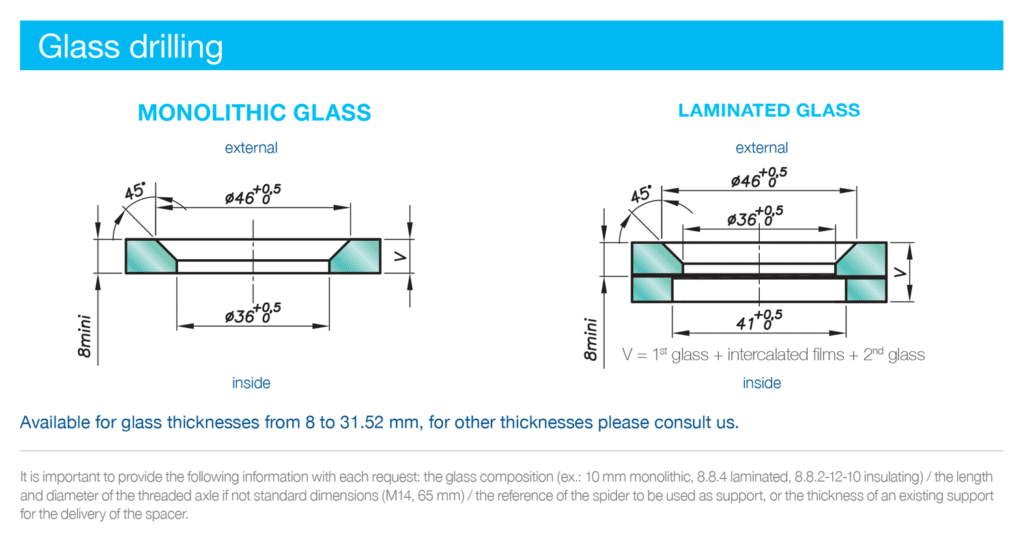

- Cylindrical drilling

- Stainless steel AISI 316

- Validated for an explosion-proof building

- Validated all seismic zones

- Optional sealing bellows

- Application: Double Skin Façade, glass curved facade, point fixed facade, curtain wall, solar shading, glass elevator, awnings, canopies, etc. (carried and hung)

- Application on curved glazing possible

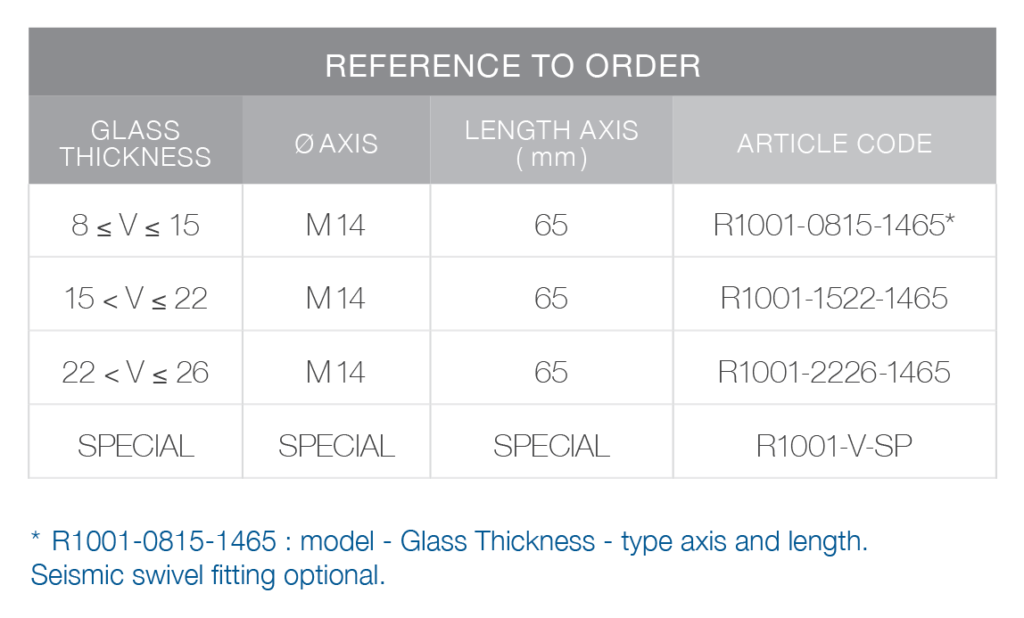

- Several diameters and axis lengths available

- High mechanical performance

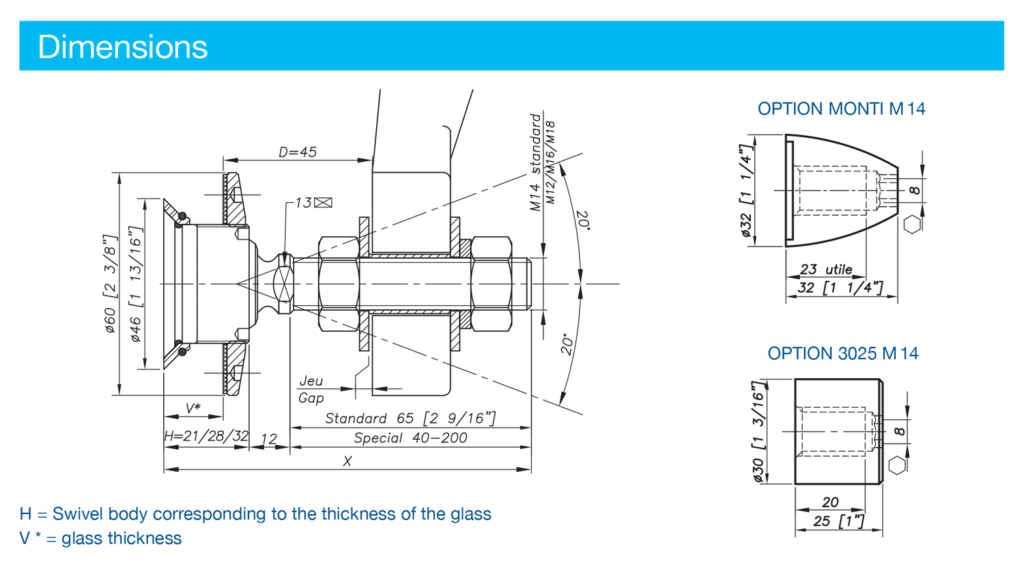

- 20° deflection + or – 20°

- Absorption of stresses and deformations of the glazing, therefore no stresses in the glass

- Standard assembly

- Customisation of finishes possible (colour, treatment, dimensions, etc.).

- Swivel system with backlash recovery

- Glass: mounting on laminated or monolithic glass

Swivel fitting, cylindrical head.

Application: façade, glass roof or railing.

Also suitable for suspended ceiling.

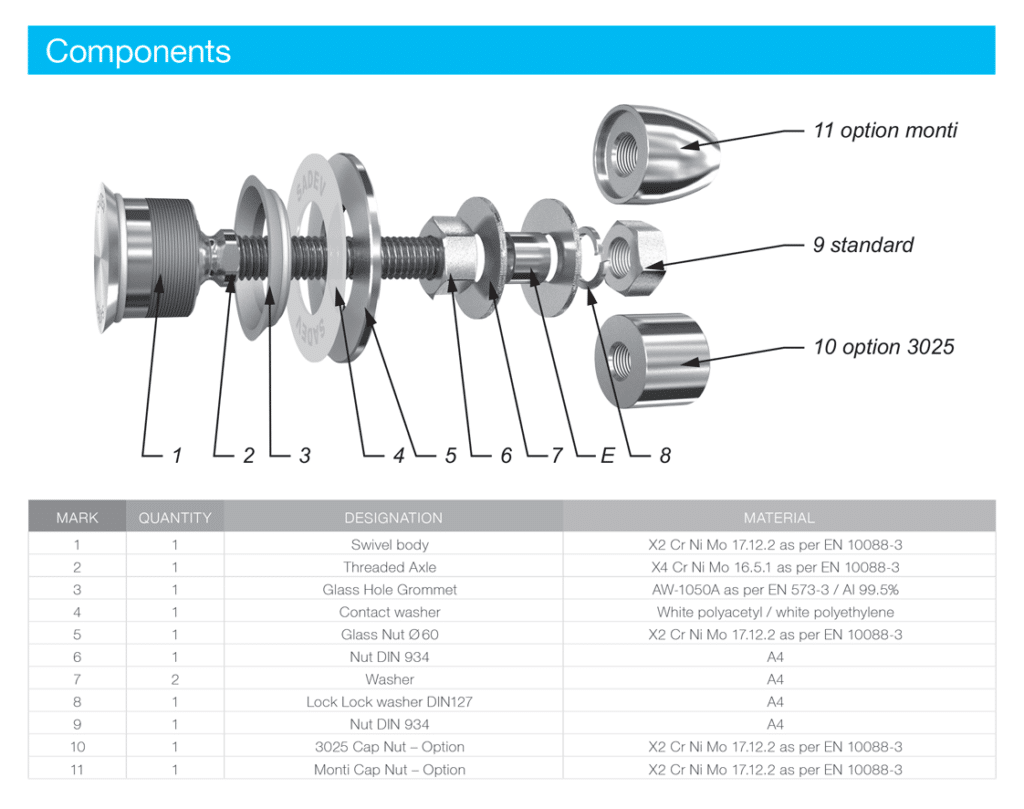

Standard threaded axle M 14, 65 mm long.

M12, M16, M18 alternatives possible.

Tailor made threaded length.

Installation from the rear, on the structure.

Different options available for this model:

R1003 SO with silicon cover (technical evaluation),

R1003 Ø 70 (technical evaluation), a Ø 70 instead of 60 swivel head in order to increase the load carrying capacity of the bolt (in case of glass roof or suspended ceiling),

R1003 Ø 70 SO (technical evaluation), R1003 with a Ø 70 swivel head and its silicon cover.

More information on the attached PDF.

R1003 is the the french technical evaluation.

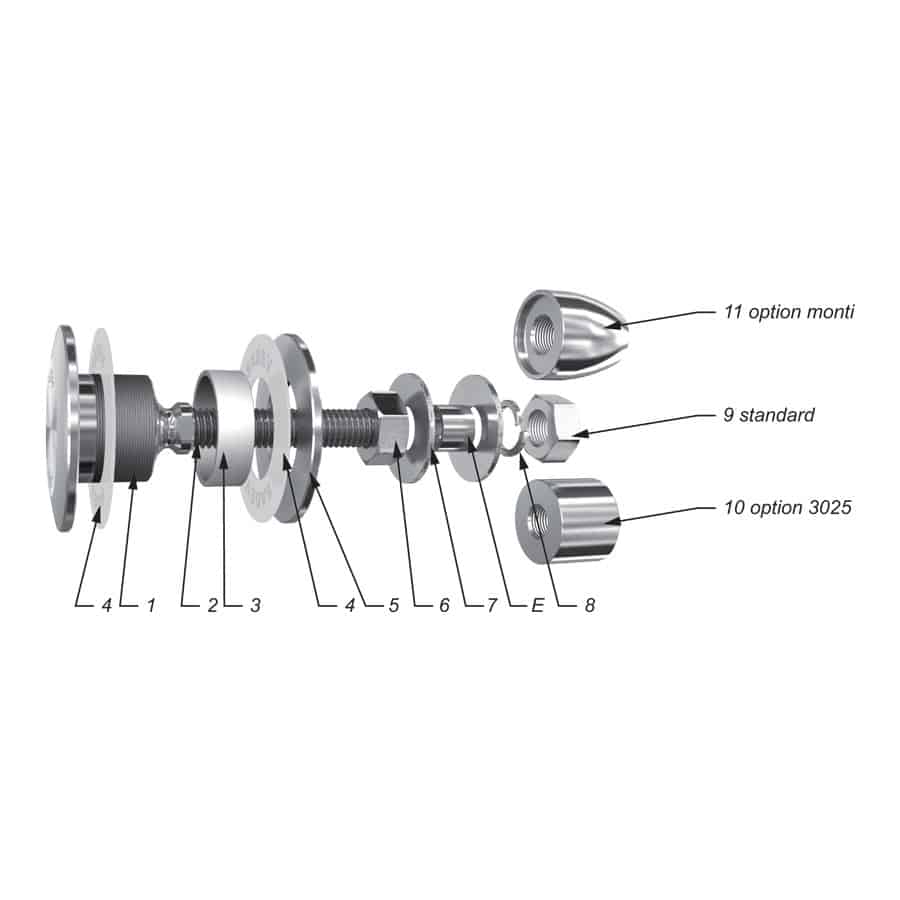

Insert parts N° 1/2 , 4, and 3 into the glass.

Mount contact washer N° 4 and nut N° 5 and tighten to 20 Nm ( 15 ft-lb ) for monolithic glass and 10 Nm ( 7.5 ft-lb ) for laminated glass using SADEV tools ref. 097581160 and ref. CLE-DYN-072031. Mount nut N° 6 and washer N° 7.

Insert the threaded axle into the support with spacer E ( available on request ), see technical page. Adjust the depth. Mount washer N° 7, lock washer N° 8, and nut N° 9. Tighten to 60 Nm ( 45 ft-lb ) using a 22 mm wrench.

SADEV recommends using thread locking compound whenever possible.