Swivel fitting - rotule - for structural bolted glass - for insulated glass - Fixed on the first glass layer - bomb blast resistant

- Non-through fixing: Insertion in insulating glass units

- Thermal bridge failure

- Stainless steel AISI 316

- Validated for buildings classified as explosion-proof

- Application: Double Skin Façade, point fixed facade, curtain wall, solar shading, glass elevator, awnings, canopies, etc. (carried and hung)

- Several diameters and axis lengths available

- High mechanical performance

- 20° deflection + or – 20°

- Absorption of stresses and deformations of the glazing, therefore no stresses in the glass.

- Blind mounting: installation from the outside (no access to the structure) or standard mounting

- Customisation of finishes possible (anodising of the aluminium insert, colour, dimensions, etc.).

- Swivel system with backlash recovery

- Glass: mounting on laminated or monolithic glass

Swivel fitting, cylindrical head – for insulated glass.

Fixed on the first glass layer.

Aesthetic solution as the first glass layer won’t have any drilling.

Particularly recommanded for a vertical façade application (inclined façade possible).

The first glass layer must be laminated.

Standard dimensions: M14, length : 65 mm. M12, M16, M18 possible on request.

Tailor-made threaded axle.

No technical evaluation.

Patented model.

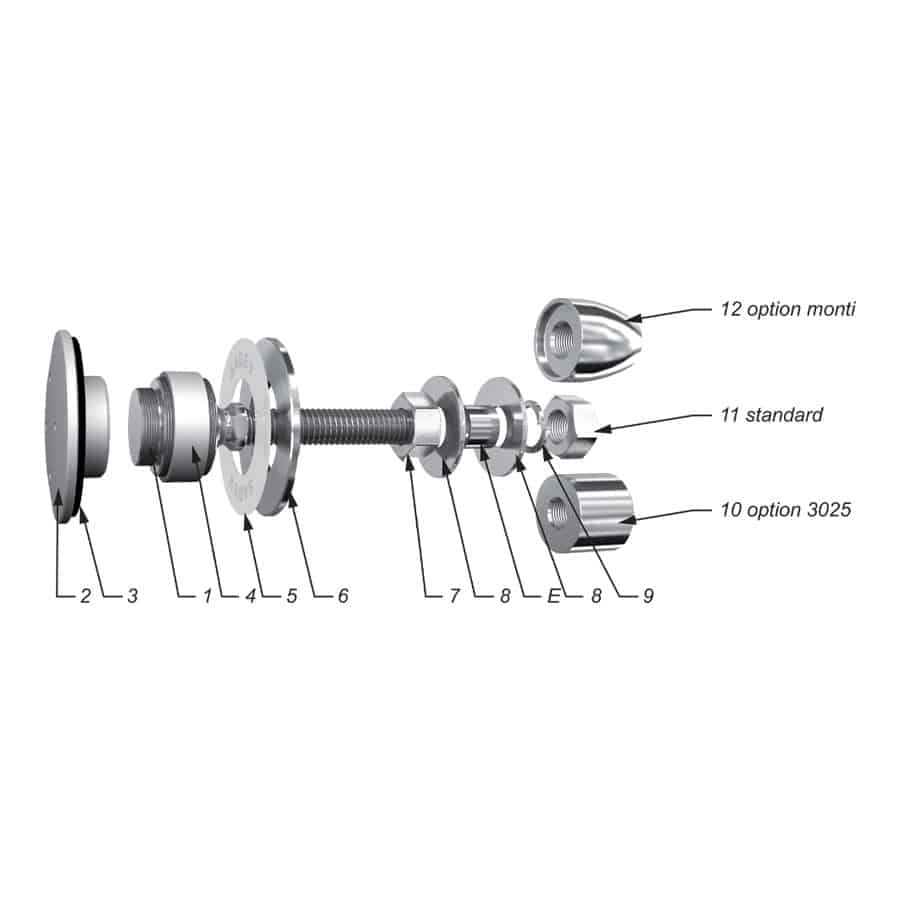

1 – In factory :

Mount parts N°2, 3, 4 into the glass with a Butyl sealing strip (not included).

Assembly by isolating glazing.

2 – On site

Mount the N°1 into bush N°2.

Attach contact washer N° 5 and glass nut N° 6 and tighten to 10 Nm ( 7.5 ft-lb )

for laminated glass using SADEV ref. 097581160 and ref. CLE-DYN-072031.

Butyl cord applied between item 1 and the glass.

Mount nut N° 7 and washer N° 8.

Insert the threaded axle into the support with spacer E ( available on request ), see technical page. Adjust the depth. Mount washer N° 8, lock washer N° 9, and tighten to 60 Nm ( 45 ft-lb ) using a 22 mm wrench.

SADEV recommends using thread locking compound whenever possible.