Clamp swivel fitting for glass wall

- Economical: no drilling & easy to install

- Stainless steel AISI 316

- Compatible with the complete range of VEA SADEV fasteners

- Innovative solution

- Insulating function possible

- Application: Double Skin Façade, glass curved facade, point fixed facade, curtain wall, solar shading, glass elevator, awnings, canopies, etc. (to be avoided in the suspended version)

- Several diameters and axis lengths available.

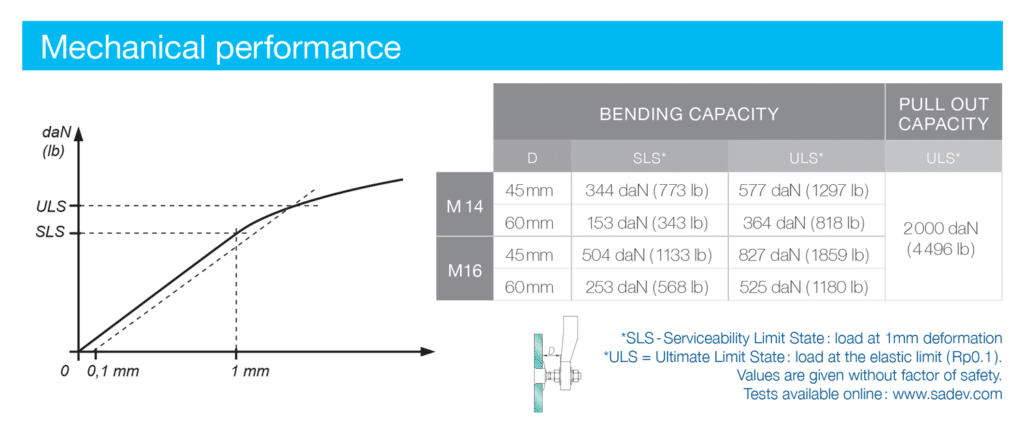

- High mechanical performance

- 20° deflection + or – 20°.

- Clamped mounting, between glass

- Customization of finishes possible (color, treatment, dimensions…)

- Swivel system with backlash recovery

- Glass: mounting on laminated or monolithic glass

Clamp swivel fitting for glass wall

Introduction to ties for glass facade

The fastening systems developed by Sadev ensure a performance and design, with maximum transparency. Thanks to a new fixing process, glass panels are supported even in cases of heavy applied loads, to guarantee a unique aesthetic design incorporting gentle curves and exceptional finish.

It requires no glass drilling, allowing easy and quick installation. Parts are made out of 316 Stainless Steelwith a brushed finish (standard) allowing installation in both interior and exterior environments and nearly any condition.

The advantages of clamp fixing system

Sadev supply a full product range, with 1,2 or 4 arms spiders in order to answerto each glass wall project. This systemforms an economical and state-of-the art solution, since she is an excellent alternative to the traditional glass fixing system without drilling of hte glass.

Fixing parts allow to realize projects simple as well as complexes, for glasses from 8 to 31,52 mm, with possible insulating function. Sadev offers you a turnkey solution for a glass wall facade thanks to the curves of parts and the absence of driiling.

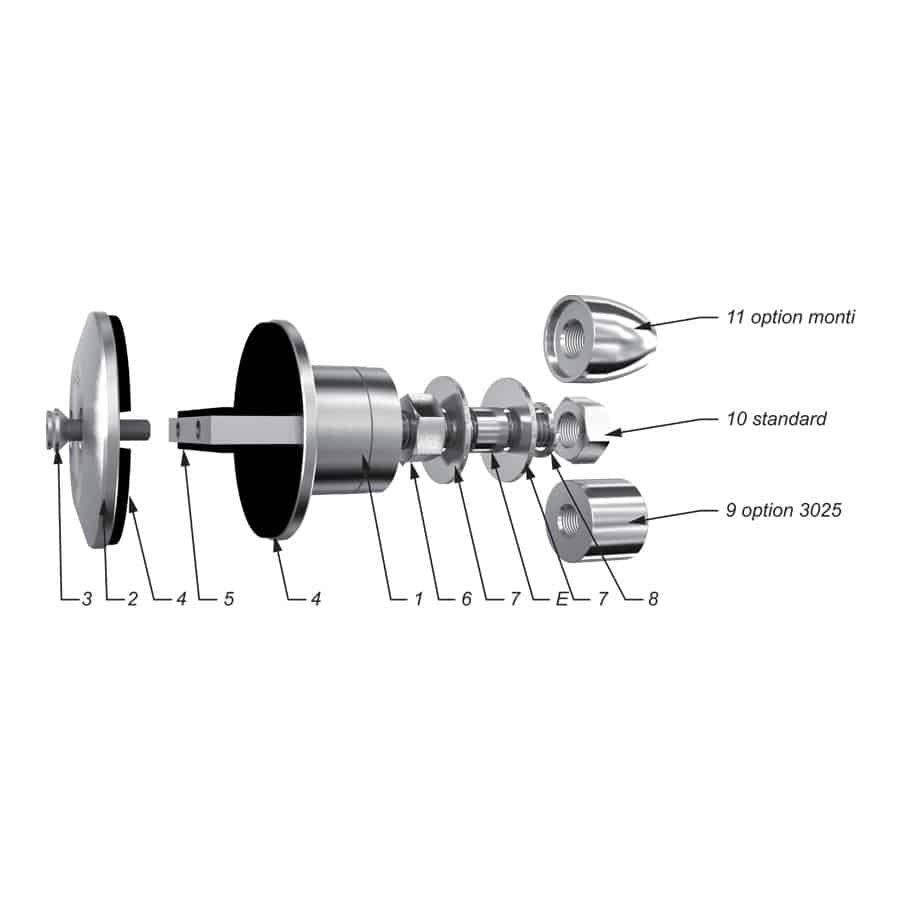

RC70 Swivel fitting

The swivel fitting RC70 is designed specifically for glass clamp facades, and has technical advice. It is composed of an axis of Ø14 mm diameter and 65 mm lenght in standard size. No glass drilling.

Suggested mounting instruction

Install the nut (# 6) + 1 washer (#7) on part (#1).

Install through the hole in the support or spider casting. Spacer E over threads to prevent

fitting from fully tightening on support for differential movements between structure

and glass support (supplied on request). Adjust depth in or out as needed.

Mounting other washer (#7) and lock washer (#8) + nut (#9, 10 (standard), or 11) and

torque to 60 Nm (45 ft lbs). Set glass on gravity shelf with EDPM (#5) setting block.

Mount the external disc (#2) with EPDM (#4) washer between glass and metal using 2

screws (#3) provided. Torque screws to 20 Nm (15 ft lbs) for monolithic glass and 10

Nm (8 ft lbs) for laminated (PVB) glass using a 4mm hex wrench.

Sadev recommends using tread locker on the external clamping screws on exterior applications.